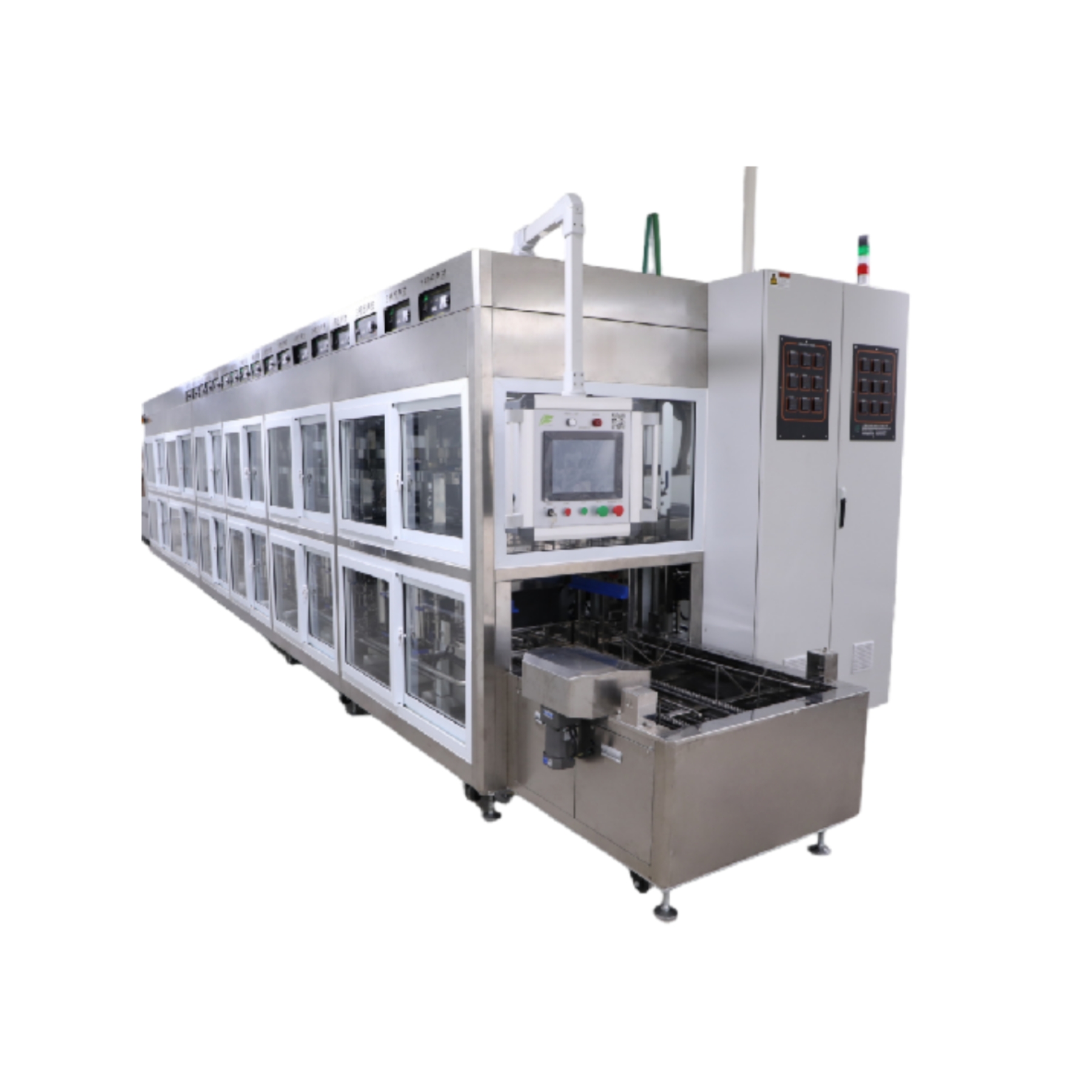

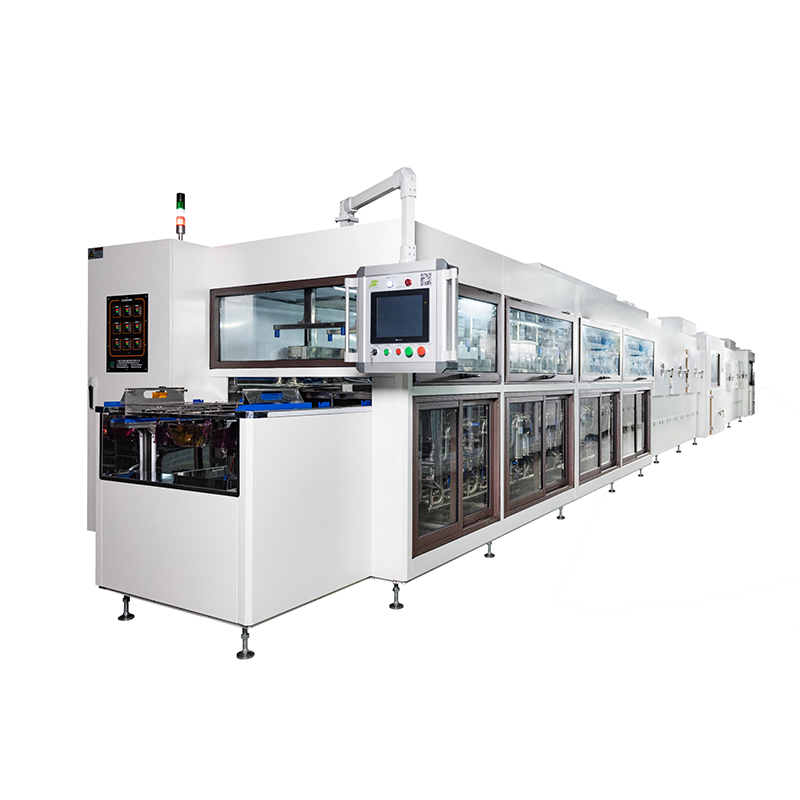

I. Equipment Overview

This semiconductor target material cleaning machine is a dedicated device specially designed for surface treatment of target material components in the semiconductor industry. Its core function is to remove oil stains, oxide films, metal particles, organic contaminants and other impurities on the surface of semiconductor targets through a multi-process coordinated cleaning process, ensuring that the target surface meets the ultra-high cleanliness (particle size ≤0.1μm) and low roughness requirements required by the semiconductor sputtering process, and providing high-quality target substrates for subsequent sputtering coating processes. Ensure the uniformity and performance stability of the coating layer.

The equipment adopts a fully automatic PLC control system, integrating pre-cleaning, ultrasonic cleaning, chemical cleaning, pure water rinsing, vacuum drying and other integrated processes. It features high cleaning efficiency, high cleanliness compliance rate, low target material damage rate, intelligent operation and environmental compliance. It is widely applied in the surface pretreatment process of various metal and alloy targets such as semiconductor aluminum targets, copper targets, titanium targets and tungsten targets, and is one of the key supporting equipment in the sputtering stage of semiconductor chip manufacturing.

II. Main Technical Parameters

Parameter name | Parameter value |

Handle the size range of the target material | Diameter: 200mm - 800mm, thickness: 5mm - 50mm |

Single processing quantity | 1-2 pieces (adjusted according to the size of the target material, with independent fixtures for fixation) |

Volume of the cleaning tank | 100L - 500L (Slot design) |

Ultrasonic cleaning frequency | 28kHz - 130kHz (Multi-frequency adjustable, suitable for removing different impurities) |

Cleaning temperature control range | 25℃ - 70℃(±0.5℃) |

Rinsing method | Three-stage pure water countercurrent rinsing + megasonic rinsing |

Drying method | Nitrogen purging + vacuum low-temperature drying (40℃ - 60℃) |

Resistivity requirements for pure water | ≥18.2MΩ·cm(25℃) |

Total power of the equipment | 20kW - 45kW |

Requirements for compressed air/nitrogen | 0.6MPa - 0.9MPa,Class 1 cleanliness |

III. Equipment Structure Composition

3.1 Multi-process cleaning system

The multi-process cleaning system consists of a pre-cleaning tank, an ultrasonic cleaning tank, a chemical cleaning tank and an auxiliary liquid medicine system. The pre-cleaning tank adopts a high-pressure spray method to initially remove large particle impurities on the surface of the target material. The ultrasonic cleaning tank is equipped with a multi-frequency ultrasonic generator and vibration plates. Through the synergistic effect of ultrasonic waves of different frequencies, it efficiently removes tiny particles and adhering contaminants. The chemical cleaning tank is made of corrosion-resistant materials (such as PVDF) and is equipped with a liquid medicine circulation and filtration device. It precisely controls the concentration and temperature of the liquid medicine to achieve targeted removal of oxide films and organic pollutants. The auxiliary liquid medicine system includes liquid medicine proportioning, transportation and recovery units, ensuring the accuracy and environmental friendliness of liquid medicine usage.

3.2 Rinse system

The rinsing system includes a three-stage countercurrent rinsing tank, a megasonic rinsing tank, and a pure water preparation and circulation device. The three-stage countercurrent rinsing tank adopts a stepped water level design. The rinsing wastewater from the previous stage is used as the rinsing water for the next stage, significantly enhancing the utilization rate of water resources. The megasound rinsing tank utilizes high-frequency megasound waves (above 1MHz) to enhance the removal of sub-micron residual impurities on the surface of target materials. The pure water preparation device integrates reverse osmosis, EDI and other processes, continuously supplying high-purity pure water. The pure water after rinsing can be partially reused after circulation and filtration.

3.3 Drying System

The drying system consists of a nitrogen purging device, a vacuum drying tank and a temperature control system. The nitrogen purging device adopts a ring-shaped nozzle design, which can purge the surface moisture of the target material in 360° without blind spots, and the nitrogen purity is ≥99.999%. The vacuum drying tank can achieve a vacuum degree of 0.001MPa to 0.01MPa, and when combined with low-temperature heating at 40℃ to 60℃, it can quickly remove residual moisture while preventing the oxidation of target materials. The temperature control system adopts PID regulation to ensure stable temperature during the drying process.

3.4 Control System

The control system adopts a control architecture of PLC (Programmable Logic Controller) + industrial touch screen, supporting both Chinese and English operation interfaces. It can achieve full process automatic operation and also perform single-step manual debugging. The touch screen displays key parameters such as the temperature, liquid level, ultrasonic power and vacuum degree of each tank in real time. It is equipped with functions such as parameter storage, process invocation, fault alarm (sound and light alarm + screen prompt), and historical data traceability (≥1 year), meeting the traceability requirements of the semiconductor industry.

3.5 Safety and Environmental Protection System

The safety and environmental protection system includes liquid leakage detection, over-temperature and over-pressure protection, emergency stop interlock, waste gas treatment and waste liquid recovery devices. The liquid medicine leakage detection device adopts high-precision sensors. When leakage occurs, it immediately cuts off the supply of liquid medicine and alarms. Over-temperature and over-pressure protection covers each tank and pressure unit to ensure the safe operation of the equipment. Emergency stop buttons are distributed on the operation and maintenance surfaces of the equipment to achieve emergency shutdown. The waste gas treatment device achieves standard discharge through activated carbon adsorption and acid mist neutralization. The waste liquid recovery device classifies and collects the chemical cleaning waste liquid and rinsing wastewater, facilitating subsequent treatment.

This equipment can be designed, developed and manufactured according to different product specifications and production capacities.

Slovenian

Slovenian

Slovak

Slovak

Latvian

Latvian

Bosnian

Bosnian

Icelandic

Icelandic

Ukrainian

Ukrainian

Georgian

Georgian

Serbian

Serbian

Croatian

Croatian

Belarusian

Belarusian

Romanian

Romanian

Estonian

Estonian

Hungarian

Hungarian

Czech

Czech

Catalan

Catalan

Norwegian

Norwegian

Lithuanian

Lithuanian

Albanian

Albanian

Hindi

Hindi

Italian

Italian

Finnish

Finnish

Arabic

Arabic

Danish

Danish

Bulgarian

Bulgarian

Thai

Thai

Polish

Polish

Swedish

Swedish

Greek

Greek

Portuguese

Portuguese

Dutch

Dutch

Spanish

Spanish

Turkish

Turkish

Russian

Russian

Deutsch

Deutsch

French

French

Korean

Korean

Japanese

Japanese

English

English

Leave A Comment