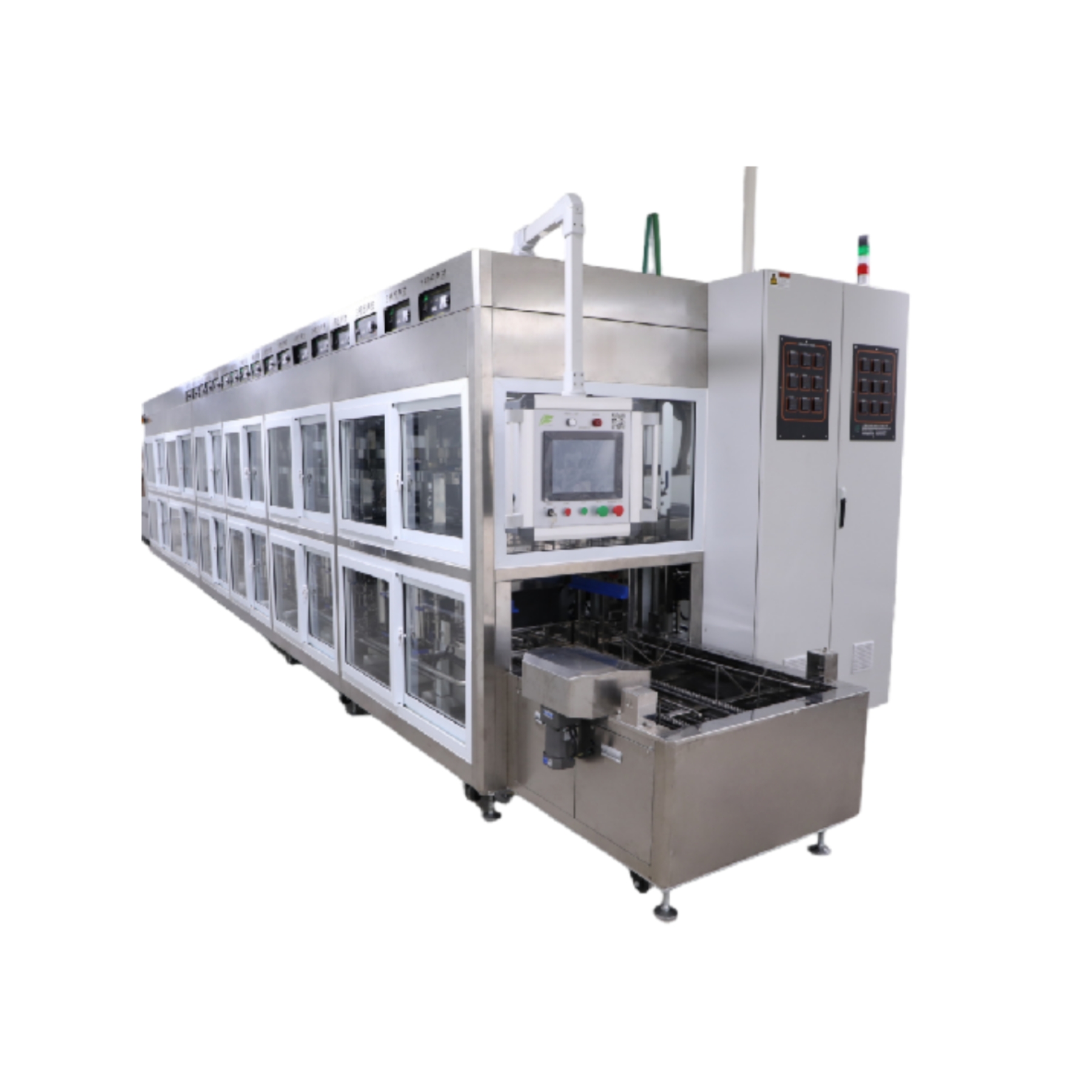

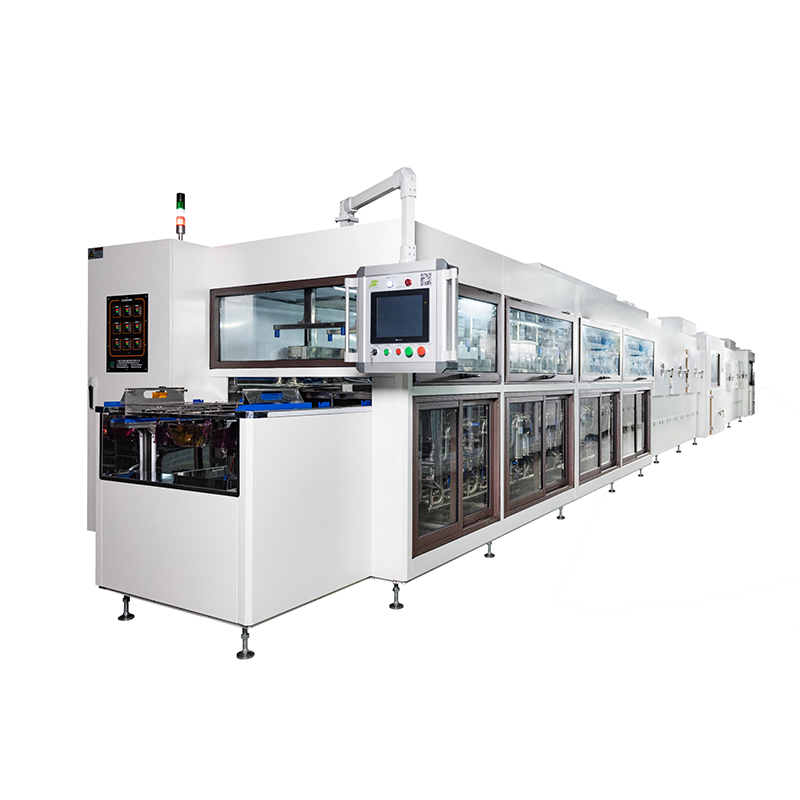

I. Equipment Overview

This semiconductor ring component pickling machine is a dedicated device specially designed for surface treatment of ring components in the semiconductor industry. Its core function is to remove contaminants such as oxide layers, oil stains, and metal impurities on the surface of semiconductor rings through precisely controlled acid washing processes, ensuring that the surface of the rings meets the high cleanliness and surface roughness requirements for semiconductor manufacturing, and providing a high-quality substrate surface for subsequent coating, packaging, and other processes.

The equipment adopts a fully automatic control system, integrating integrated processes such as acid washing, rinsing and drying. It features high processing efficiency, stable acid washing effect, simple operation, safety and environmental protection. It is widely used in the surface treatment processes of key ring components such as semiconductor silicon wafer carrier rings and wafer transfer rings, and is one of the indispensable important equipment in the semiconductor manufacturing process.

II. Main Technical Parameters

III. Equipment Structure Composition

3.1 Pickling system

The acid washing system consists of an acid washing tank, a heating device, a stirring device, an acid filtration device and an acid concentration detection device. The acid washing tank is made of corrosion-resistant materials such as PP and PVDF, and has excellent acid resistance. The heating device adopts stainless steel heating tubes and achieves precise control of the pickling temperature through a PID temperature control system. The stirring device adopts pneumatic stirring or mechanical stirring methods to ensure uniform concentration of the acid solution. The acid filtration device can remove impurity particles from the acid solution to ensure the acid washing effect. The acid concentration detection device monitors the acid concentration in real time. When the concentration is lower than the set value, it automatically alarms to prompt the replacement or replenishment of the acid.

3.2 Rinse system

The rinsing system consists of multi-stage rinsing tanks, ultrasonic generation devices, pure water supply devices and drainage devices. The multi-stage rinsing tank adopts counter-current rinsing design to improve the utilization rate of water resources. The ultrasonic generating device produces high-frequency ultrasonic waves, which can effectively remove residual acid and tiny impurities on the surface of the ring parts. The pure water supply device provides high-purity pure water (resistivity ≥18.2MΩ·cm) that meets the standards of the semiconductor industry. The drainage device is equipped with a waste liquid treatment interface, facilitating the centralized treatment of rinsing waste liquid.

3.3 Drying System

The drying system consists of a drying tank, a hot air device, a vacuum device and a temperature control device. The hot air device adopts high-efficiency heaters and fans to blow out clean hot air. The vacuum device can reduce the air pressure inside the drying tank and accelerate the evaporation rate of water. The temperature control device ensures that the drying temperature remains stable within the set range, preventing the ring parts from being damaged due to excessively high temperatures.

3.4 Control System

The control system adopts a control mode of PLC (Programmable Logic Controller) + touch screen, featuring an excellent human-machine interaction interface. It can achieve fully automatic control of processes such as acid washing, rinsing and drying, and can also be operated manually. The touch screen can display the operating status, parameter set values and actual values of each process, and also has functions such as fault alarm and historical data query.

3.5 Safety Protection System

The safety protection system includes acid leakage detection devices, over-temperature protection devices, overcurrent protection devices, emergency stop buttons and ventilation and exhaust devices. The acid leakage detection device can promptly detect acid leakage and issue an alarm. The over-temperature protection device automatically stops heating when the pickling temperature or drying temperature exceeds the set upper limit. The overcurrent protection device automatically cuts off the power supply when an overcurrent fault occurs in the equipment circuit. The emergency stop button can quickly halt the operation of the equipment in an emergency. The ventilation and exhaust device promptly dissolves the acid mist generated during the pickling process, ensuring the physical health of the operators.

This equipment can be designed, developed and manufactured according to different product specifications and production capacities.

Slovenian

Slovenian

Slovak

Slovak

Latvian

Latvian

Bosnian

Bosnian

Icelandic

Icelandic

Ukrainian

Ukrainian

Georgian

Georgian

Serbian

Serbian

Croatian

Croatian

Belarusian

Belarusian

Romanian

Romanian

Estonian

Estonian

Hungarian

Hungarian

Czech

Czech

Catalan

Catalan

Norwegian

Norwegian

Lithuanian

Lithuanian

Albanian

Albanian

Hindi

Hindi

Italian

Italian

Finnish

Finnish

Arabic

Arabic

Danish

Danish

Bulgarian

Bulgarian

Thai

Thai

Polish

Polish

Swedish

Swedish

Greek

Greek

Portuguese

Portuguese

Dutch

Dutch

Spanish

Spanish

Turkish

Turkish

Russian

Russian

Deutsch

Deutsch

French

French

Korean

Korean

Japanese

Japanese

English

English

Leave A Comment