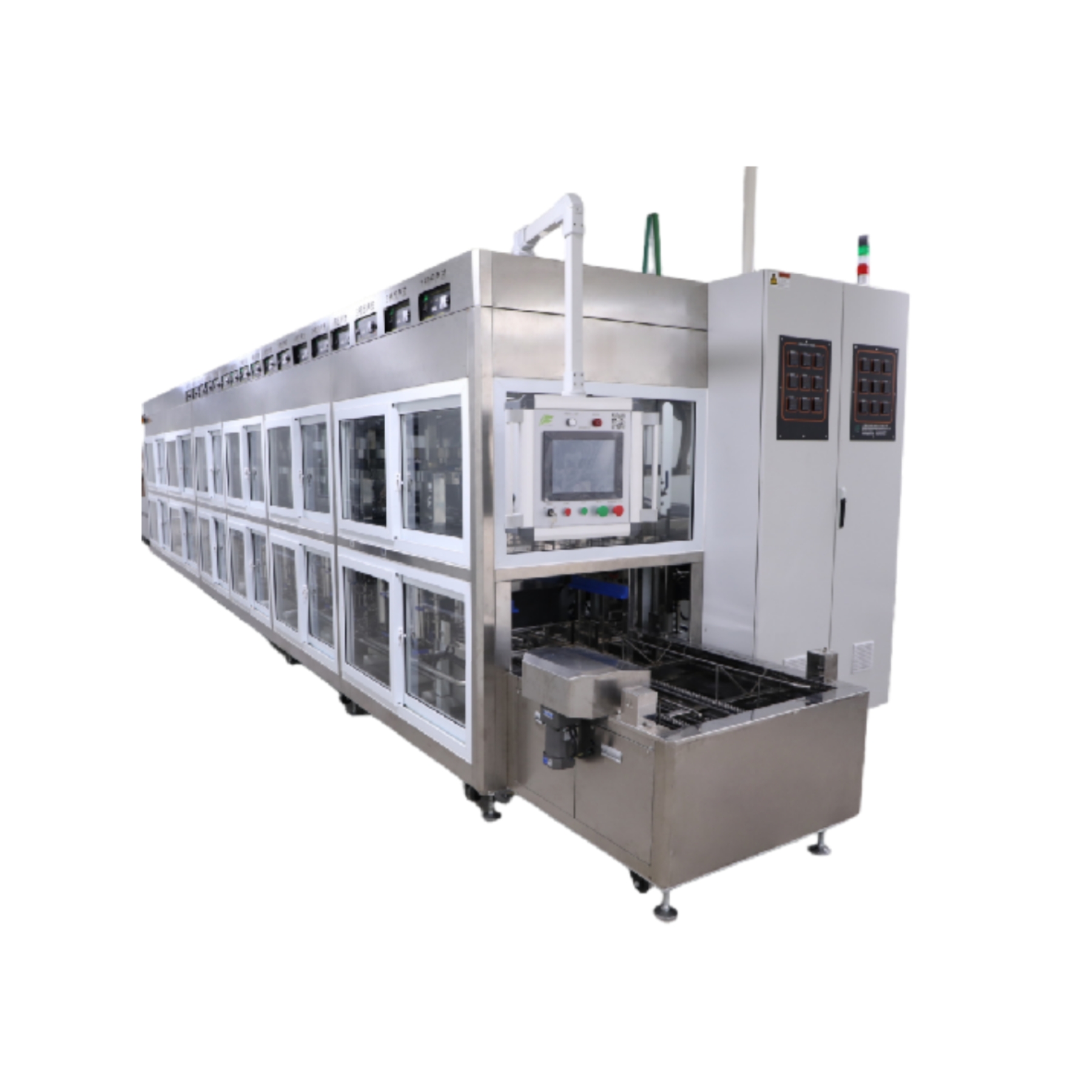

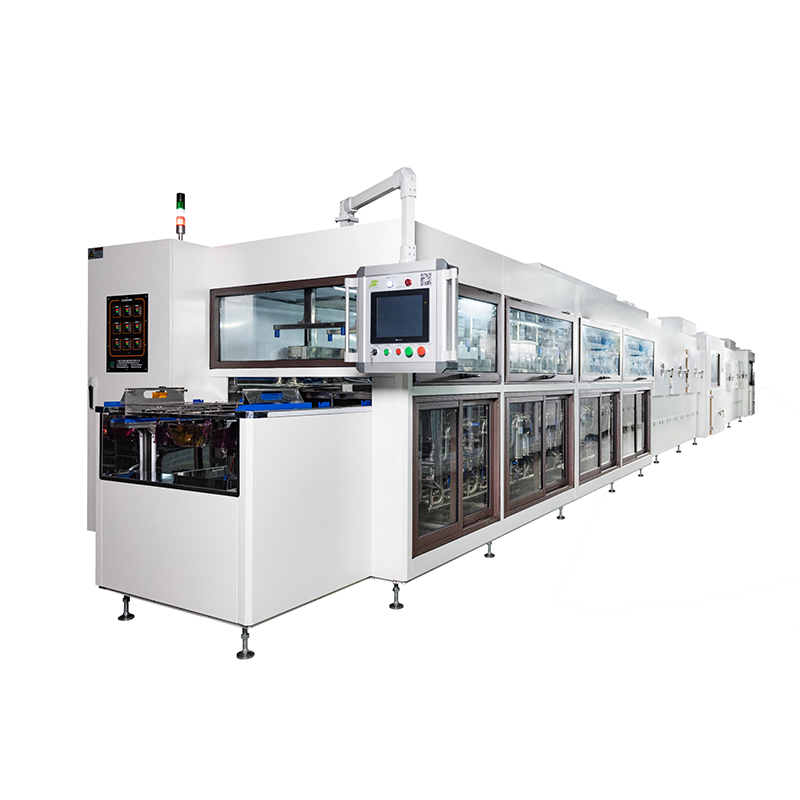

Product Introduction

The fully automatic ceramic tile cleaning machine is an intelligent cleaning device specially designed for ceramic tiles (including zirconia ceramic tiles, alumina ceramic tiles, silicon nitride ceramic tiles and various other industrial and civil ceramic substrates). The equipment adopts an integrated process of "pre-rinsing - ultrasonic fine cleaning - rinsing - drying", and is fully automated through a PLC programmable control system. It can effectively remove oil stains, dust, grinding residues and other contaminants on the surface of ceramic plates. After cleaning, the surface of the ceramic plates is highly clean, free of water marks and scratches. It is widely applied in the production and processing links of industries such as electronic components, precision machinery, ceramic tableware, and architectural ceramics.

Core advantage

- High degree of automation: No human intervention is required throughout the process. It supports single-batch batch cleaning and continuous assembly line operations, significantly enhancing production efficiency.

- Excellent cleaning effect: By combining multi-frequency ultrasonic waves (adjustable at 28KHz, 40KHz, and 80KHz) with high-pressure spray technology, there are few blind spots in cleaning, and the removal rate of contaminants exceeds 99%.

- Gentle and non-destructive: The temperature of the cleaning solution and the ultrasonic power can be precisely controlled. When paired with a dedicated neutral cleaning agent, it can prevent scratches on the surface of the ceramic plates or damage to the material.

- Energy conservation and environmental protection: By adopting a closed-loop water circulation system, the cleaning liquid can be filtered, recycled and reused, increasing the utilization rate of water resources by 60%. The drying process is equipped with a waste heat recovery device, reducing energy consumption by 30%.

- Safe and reliable: Equipped with multiple safety devices such as overload protection, leakage protection, liquid level alarm, and high-temperature warning, it ensures the stable operation of the equipment and the safety of the operators.

Core component

1. Ultrasonic generation system: Composed of an ultrasonic generator and transducers, the transducers are evenly distributed at the bottom and sides of the cleaning tank to ensure uniform coverage of ultrasonic energy.

2. Conveying system: Stainless steel mesh belts or special fixtures are used for conveying. The conveying speed is adjustable from 0.5m/min to 3m/min, suitable for ceramic plates of different sizes.

3. Temperature control system: Equipped with high-precision temperature sensors and heating tubes, it can monitor and regulate the temperature of the cleaning solution and drying in real time.

4. Filtration system: The cleaning tank is equipped with a 5μm precision filter inside, which can filter impurities and extend the service life of the cleaning solution.

5. Drying system: It includes a hot air generator, circulating fan and air outlet. The hot air is evenly blown to ensure the rapid drying of ceramic plates.

6. Control System: It adopts touch screen + PLC control, with an intuitive interface. It can set cleaning parameters, store process plans, and view the operation status.

This equipment can be designed, developed and manufactured according to different product specifications and production capacities.

Slovenian

Slovenian

Slovak

Slovak

Latvian

Latvian

Bosnian

Bosnian

Icelandic

Icelandic

Ukrainian

Ukrainian

Georgian

Georgian

Serbian

Serbian

Croatian

Croatian

Belarusian

Belarusian

Romanian

Romanian

Estonian

Estonian

Hungarian

Hungarian

Czech

Czech

Catalan

Catalan

Norwegian

Norwegian

Lithuanian

Lithuanian

Albanian

Albanian

Hindi

Hindi

Italian

Italian

Finnish

Finnish

Arabic

Arabic

Danish

Danish

Bulgarian

Bulgarian

Thai

Thai

Polish

Polish

Swedish

Swedish

Greek

Greek

Portuguese

Portuguese

Dutch

Dutch

Spanish

Spanish

Turkish

Turkish

Russian

Russian

Deutsch

Deutsch

French

French

Korean

Korean

Japanese

Japanese

English

English

Leave A Comment