In fields such as precision manufacturing, automotive maintenance, and electronic processing, the cleanliness of components directly determines product performance, service life, and production safety. Traditional cleaning methods such as manual wiping and high-pressure spraying often have problems such as incomplete cleaning, damage to precision components and low efficiency. This ultrasonic cleaning machine for parts, relying on advanced ultrasonic cavitation technology, achieves deep, efficient and non-destructive cleaning of various parts, providing one-stop cleaning solutions for industry users and helping to improve production quality and operational efficiency.

I. Core Advantages of the Product: Redefining the cleaning standards for components

1.Ultrasonic cavitation technology achieves micron-level deep cleaning

The core of the product is equipped with a high-frequency ultrasonic generator, which can produce adjustable ultrasonic waves in multiple frequency bands ranging from 28kHz to 130kHz. When ultrasonic waves act on the cleaning solution, countless tiny bubbles are instantly formed. Under the change of pressure, these bubbles rapidly expand and burst, generating a powerful impact force (i.e., the "cavitation effect"). This impact force can penetrate into areas of components such as threads, blind holes, gaps, and gear meshing surfaces that are difficult to reach with traditional cleaning methods, effectively stripping off various contaminants such as oil stains, carbon deposits, metal debris, flux, and oxide layers. The cleaning accuracy can reach the micrometer level, ensuring that the surface and interior of components meet strict cleaning standards.

Compared with traditional cleaning, ultrasonic cleaning does not require direct contact with the surface of components, avoiding scratches, deformations and other damages caused by manual wiping. It is especially suitable for cleaning precision parts such as bearings, gears, chips, nozzles and valve bodies.

2. Intelligent and efficient operation, taking into account both efficiency and energy conservation

In terms of efficiency, the equipment adopts a multi-frequency collaborative cleaning mode. It can intelligently match the optimal ultrasonic frequency and cleaning time based on the material of the components (such as metal, plastic, ceramic) and the type of contaminants. The cleaning capacity of a single tank can reach 5-50kg (depending on the model), and the cleaning efficiency is 5-10 times higher than manual cleaning, significantly shortening the production cycle.

In terms of energy-saving design, the equipment adopts variable frequency motors and insulated energy-saving cabins, reducing heat loss by more than 30%. It is also equipped with an intelligent sensing system. When there are no workpieces in the cleaning tank, it automatically enters standby mode, effectively reducing the waste of electricity and cleaning solution and lowering the operating costs of the enterprise.

3. Multiple safety protections ensure the safety of operation and components

The equipment has set up a complete protection mechanism from the dual perspectives of operational safety and component protection

Component protection: Supports soft-start ultrasonic function to prevent damage to precision components caused by instantaneous high-frequency impact. Equipped with an automatic temperature control system, it can stabilize the temperature of the cleaning solution at 20-80℃, meeting the cleaning requirements of components made of different materials.

Operational safety: It is equipped with multiple safety devices such as cover opening shutdown protection, overcurrent protection, overheat protection, and low liquid level alarm. The body is made of 304 stainless steel that is resistant to corrosion and high temperatures. The operation panel adopts a waterproof touch design to ensure operational safety in harsh working environments.

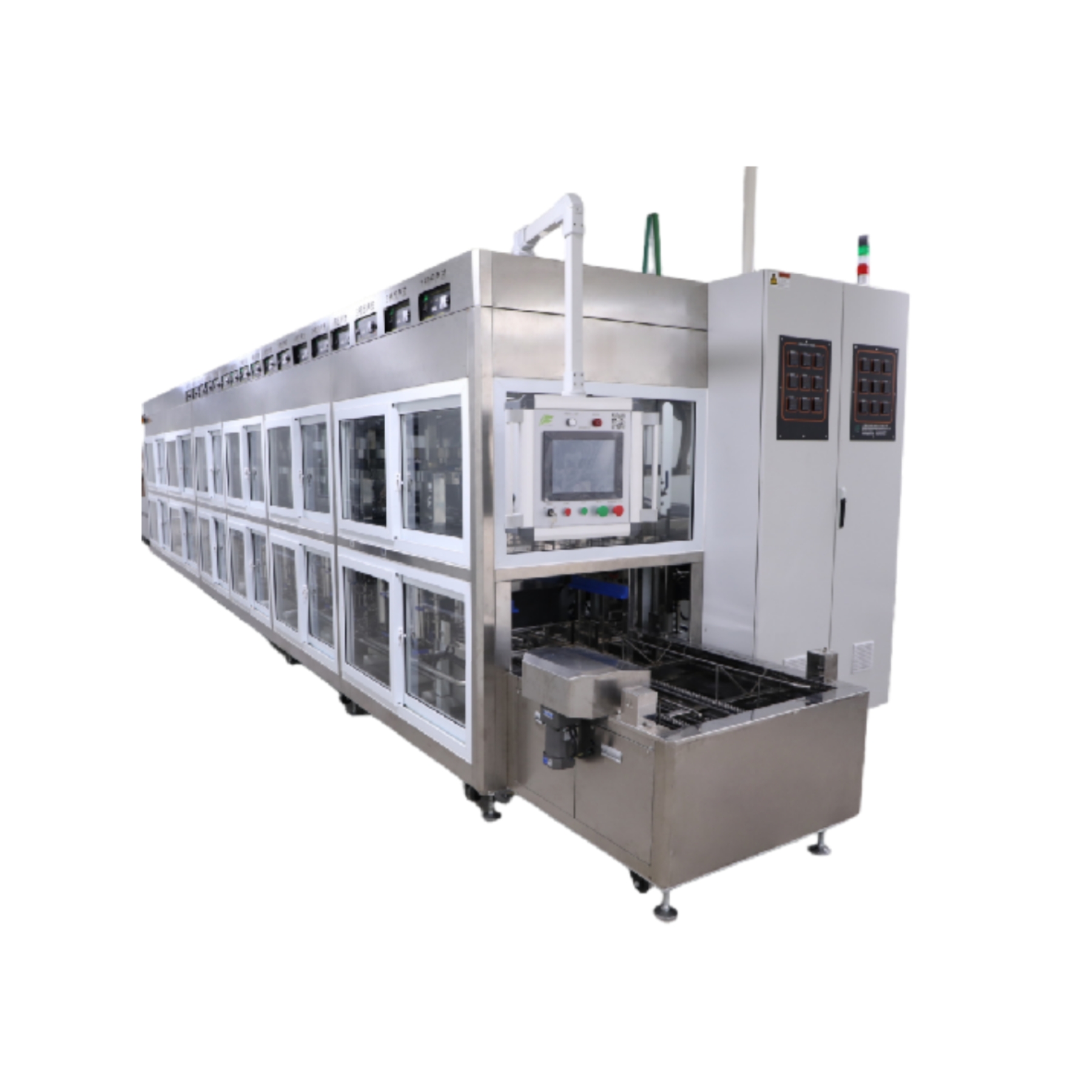

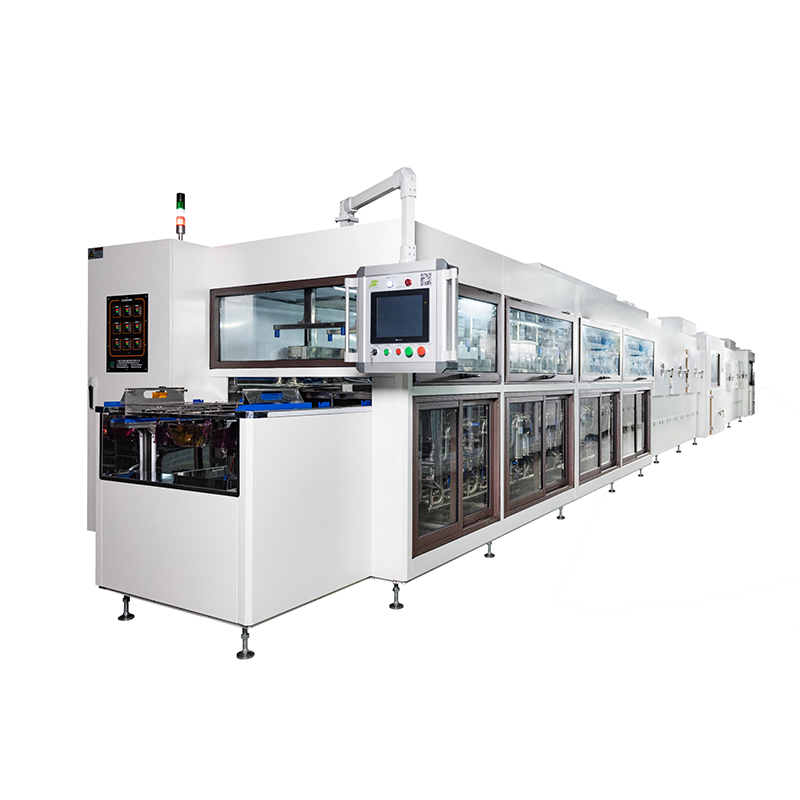

4. Flexible adaptation to meet the needs of diverse scenarios

The products include various models such as single-tank type, multi-tank type, and fully automatic assembly line type, with volumes ranging from 10L to 500L. Users can flexibly choose according to their production scale, component size, and cleaning process. Meanwhile, the equipment supports customized services. For instance, in response to the high cleanliness requirements of special industries such as military and medical, it can be equipped with additional modules like filtration circulation systems, drying systems, and vacuum degassing systems to achieve an integrated operation of "cleaning - rinsing - drying", further enhancing the cleaning effect and production continuity.

II. Applicable Scenarios: Covering the cleaning needs of multiple industries

This ultrasonic cleaning machine for components, with its strong adaptability, has been widely applied in the following fields:

1.Automobiles and construction machinery: Clean oil stains, carbon deposits and metal debris from engine pistons, fuel injectors, valves, transmission gears, hydraulic valves and other components, restore component performance and reduce maintenance costs.

2.Electronics and Semiconductors: Clean flux, solder residues, dust, etc. from the surfaces of circuit boards, chips, connectors, and electronic components to enhance the stability and service life of electronic devices.

3.Precision manufacturing and molds: Clean oil stains and cutting fluid residues from mold cavities, precision bearings, instrument and meter components, cutting tools, etc., to ensure processing accuracy and product quality.

4.Medical and biological: Clean bloodstains, tissue residues, and chemical reagents from surgical instruments, medical needles, biological laboratory equipment, etc., to meet medical-grade cleanliness standards (special medical cleaning solutions are required).

5.Aerospace and military industry: In response to the high cleanliness requirements of aviation components and military precision components, we achieve deep cleaning of complex structural parts to ensure the reliability of equipment in extreme environments.

III.. Basic Operating Procedures

- Add an appropriate amount of cleaning solution (it is recommended to use a dedicated ultrasonic cleaning solution and avoid using strongly corrosive liquids). The liquid level should cover the components and reach the specified height of the equipment.

- Place the components into the cleaning basket (it is recommended to wrap the precision parts with a special protective net), and slowly put them into the cleaning tank.

- Set the cleaning frequency, temperature and time through the touch screen and start the equipment.

- After the cleaning is completed, the equipment will automatically shut down. Remove the components and rinse the remaining cleaning solution with clean water (if drying is required, transfer to the drying module).

This equipment can be designed, developed and manufactured according to different product specifications and production capacities.

Slovenian

Slovenian

Slovak

Slovak

Latvian

Latvian

Bosnian

Bosnian

Icelandic

Icelandic

Ukrainian

Ukrainian

Georgian

Georgian

Serbian

Serbian

Croatian

Croatian

Belarusian

Belarusian

Romanian

Romanian

Estonian

Estonian

Hungarian

Hungarian

Czech

Czech

Catalan

Catalan

Norwegian

Norwegian

Lithuanian

Lithuanian

Albanian

Albanian

Hindi

Hindi

Italian

Italian

Finnish

Finnish

Arabic

Arabic

Danish

Danish

Bulgarian

Bulgarian

Thai

Thai

Polish

Polish

Swedish

Swedish

Greek

Greek

Portuguese

Portuguese

Dutch

Dutch

Spanish

Spanish

Turkish

Turkish

Russian

Russian

Deutsch

Deutsch

French

French

Korean

Korean

Japanese

Japanese

English

English

Leave A Comment