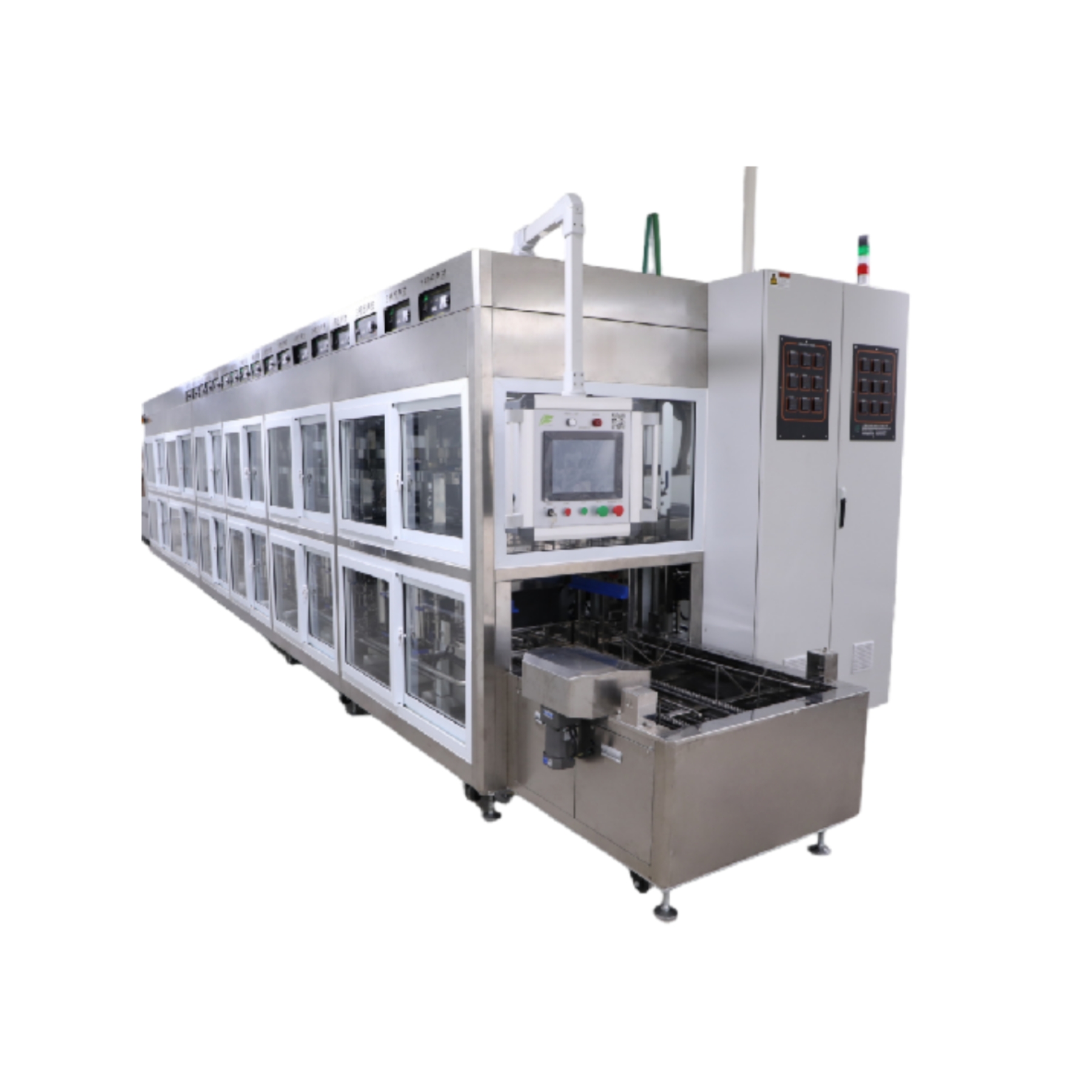

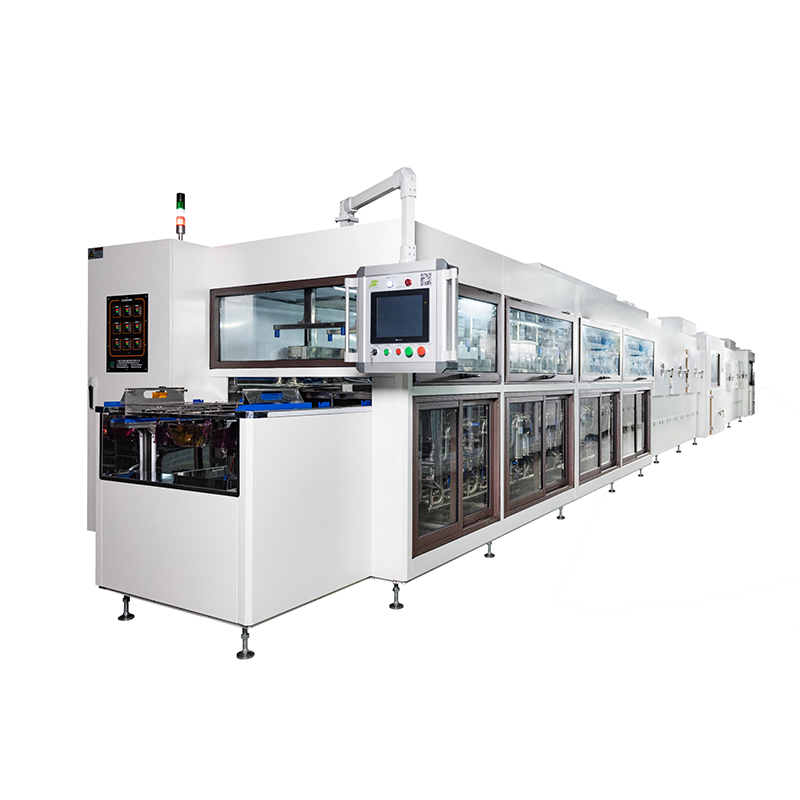

Product Introduction

Die stand is a professional mold opening machine specially designed for the forming molds of high-precision optical components such as optical glass and optical resin. After the film is closed, the mold is peeled off. The A film, B film and lenses are peeled off and then conveyed for packaging.

Its core function is to achieve precise and smooth opening and closing of the mold, ensuring that key parts such as the mold cavity and core are not damaged during the mold opening process, while meeting the strict requirements of optical molds for mold opening accuracy, speed control and stability. This equipment is widely used in scenarios such as the maintenance, cleaning, cavity inspection and product removal of high-precision optical molds like optical lens molds. It is one of the core devices for optical component manufacturing enterprises to improve mold management efficiency and ensure product quality.

Working process

1、Mold loading: Place the optical mold to be opened on the mold positioning seat on the worktable of the equipment, ensuring that the center of the mold is aligned with the center of the clamping mechanism.

2、Mold clamping: Press the "Clamping" button on the touch screen. The pneumatic clamping mechanism will automatically clamp the mold. After clamping is completed, the equipment will issue a prompt signal.

3、Parameter Settings: According to the mold specifications and mold opening requirements, set parameters such as mold opening stroke, mold opening speed (divided into three speeds: fast advance, working advance, and fast retreat), clamping force, etc. on the touch screen, or call the corresponding mold parameter program that has been stored.

4、Mold opening operation: After confirming that the parameter Settings are correct, press the "Start" button, and the equipment will start the mold opening process according to the set parameters. The servo motor drives the ball screw to move the moving template smoothly, achieving the slow opening of the mold.

5、Mold maintenance/product removal: After the mold opening is completed, the equipment automatically stops and remains in its current position. The operator can then perform operations such as cleaning the mold cavity, inspecting components, and removing products.

6、Mold closing and reset: After the maintenance operation is completed, press the "Mold closing" button. The equipment drives the template to move in the opposite direction, closing the mold. Then, the clamping mechanism is released, completing one mold opening cycle.

Slovenian

Slovenian

Slovak

Slovak

Latvian

Latvian

Bosnian

Bosnian

Icelandic

Icelandic

Ukrainian

Ukrainian

Georgian

Georgian

Serbian

Serbian

Croatian

Croatian

Belarusian

Belarusian

Romanian

Romanian

Estonian

Estonian

Hungarian

Hungarian

Czech

Czech

Catalan

Catalan

Norwegian

Norwegian

Lithuanian

Lithuanian

Albanian

Albanian

Hindi

Hindi

Italian

Italian

Finnish

Finnish

Arabic

Arabic

Danish

Danish

Bulgarian

Bulgarian

Thai

Thai

Polish

Polish

Swedish

Swedish

Greek

Greek

Portuguese

Portuguese

Dutch

Dutch

Spanish

Spanish

Turkish

Turkish

Russian

Russian

Deutsch

Deutsch

French

French

Korean

Korean

Japanese

Japanese

English

English

Leave A Comment