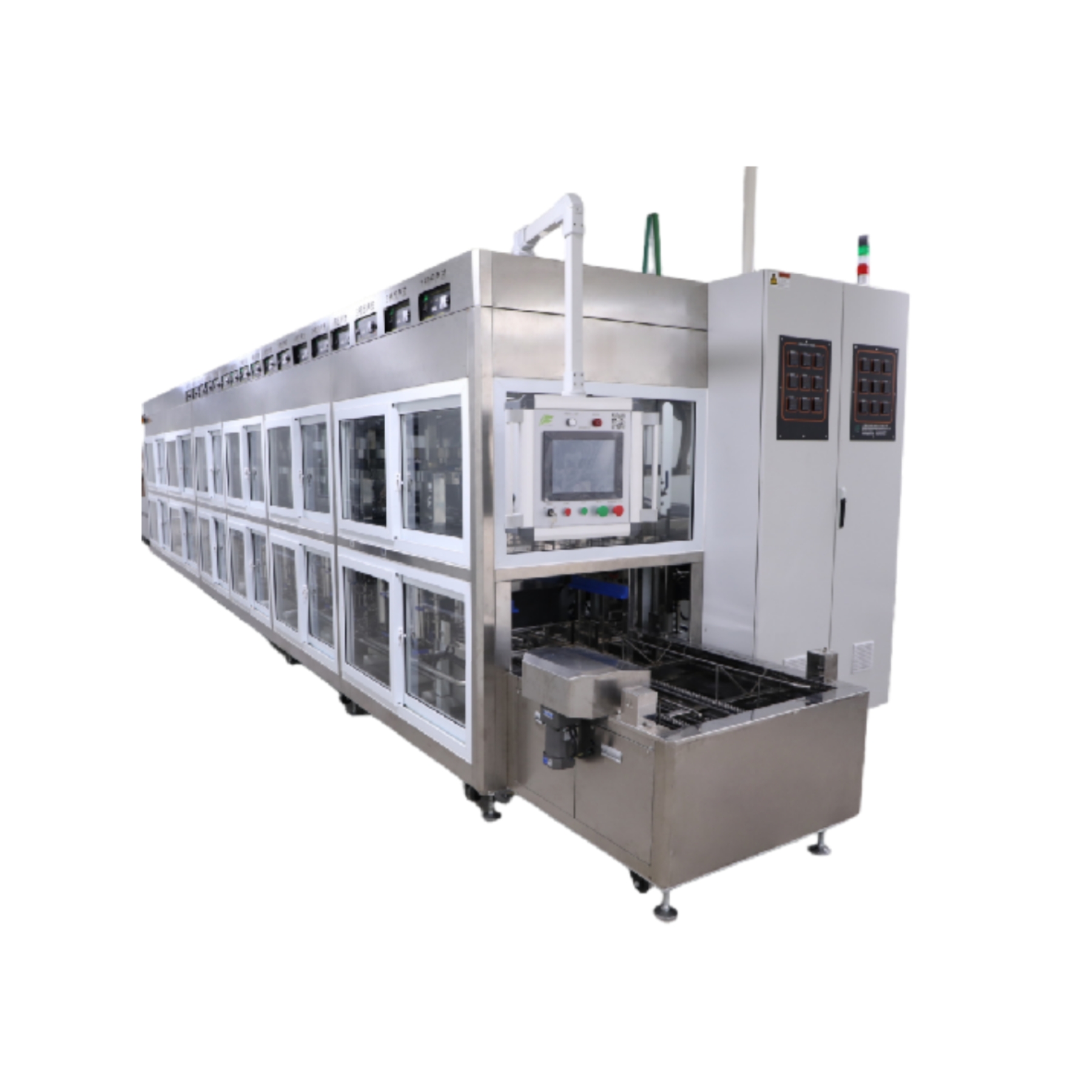

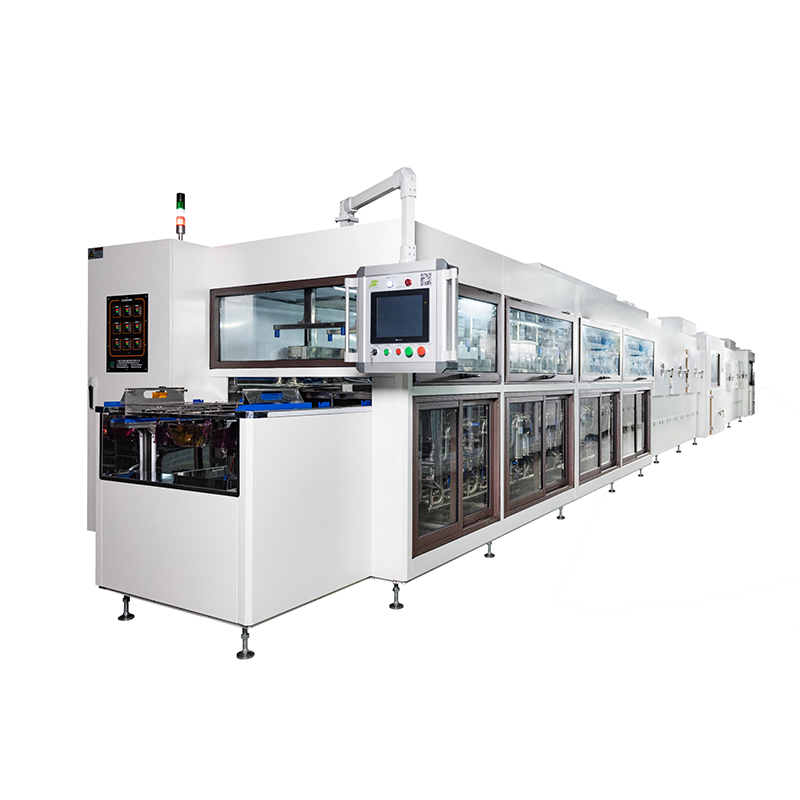

Product Introduction

Fully automatic hardware cleaning machine is a dedicated cleaning equipment specially developed for standard/irregular hardware parts, precision fasteners, stamping parts and machined parts. It integrates the integrated functions of "high-pressure precise spraying + ultrasonic assistance + rust prevention treatment + automatic drying". For contaminants such as oil stains, residual cutting fluid, metal debris, and oxide scale on the surface of hardware parts, a customized cleaning process is adopted to achieve efficient decontamination. Meanwhile, an anti-rust treatment module can be optionally equipped to ensure that the workpieces remain rust-free for a long time after cleaning. It is suitable for batch production scenarios in industries such as automobiles, machinery, electronics, and hardware manufacturing.

Cleaning parts: stamping parts, hardware parts, etc

- Each cleaning tank is respectively equipped with an ultrasonic system, a bubbling system, a filtration device and a heating device according to its own needs. Configure the exhaust system

- The feeding and discharging mechanism is equipped with sensing heads, which are respectively installed at different positions on the feeding and discharging tracks, ensuring accurate positioning.

- Both the strong wind water cutting trough and the hot air drying trough are controlled by automatic cylinder doors, which can not only reduce working noise, but also prevent liquid splashing during water cutting, keep warm and lower equipment energy consumption.

- This cleaning machine has strong decontamination ability and fast dehydration. It also features high efficiency, convenient operation, low labor intensity, high degree of automation, easy maintenance and repair, beautiful appearance and low cleaning cost.

- Work pace :5-8 minutes per basket

Core advantage (Special compatibility for hardware parts)

1. Precise adaptation to hardware structures: Equipped with adjustable fixtures and directional nozzles, it can achieve thorough cleaning of deep holes, threads, and crevices for various types of hardware parts such as screws, nuts, gears, shafts, and stamped parts without any dead corners.

2. Composite cleaning for efficient decontamination: High-pressure jet (80-250MPa) + 40kHz ultrasonic waves work in tandem to quickly remove stubborn oil stains and metal debris. The cleaning efficiency is 300% higher than that of ordinary equipment, and the single-piece cleaning time is as low as 30 seconds.

3. Integrated rust prevention and protection: An optional water-based rust inhibitor automatic dosing system is available. After cleaning, the workpiece forms a micron-level rust prevention film, and the rust prevention period for indoor storage can reach 3 to 6 months.

4. Full-process automation: PLC programmable control, supports storage of over 50 dedicated cleaning solutions for hardware parts, automatically completes the entire process from feeding, cleaning, rinsing, rust prevention, drying to discharging, without the need for manual intervention.

5. Safe, environmentally friendly and durable: Food-grade eco-friendly cleaning solution (compatible with water-based and neutral cleaning agents) is adopted, and a waste liquid filtration and recovery system is equipped, ensuring that the waste liquid discharge meets the standards. The key components (high-pressure pump, ultrasonic vibrator, fixture) are made of corrosion-resistant materials, with an MTBF of ≥8000 hours.

This equipment can be designed, developed and manufactured according to different product specifications and production capacities.

Slovenian

Slovenian

Slovak

Slovak

Latvian

Latvian

Bosnian

Bosnian

Icelandic

Icelandic

Ukrainian

Ukrainian

Georgian

Georgian

Serbian

Serbian

Croatian

Croatian

Belarusian

Belarusian

Romanian

Romanian

Estonian

Estonian

Hungarian

Hungarian

Czech

Czech

Catalan

Catalan

Norwegian

Norwegian

Lithuanian

Lithuanian

Albanian

Albanian

Hindi

Hindi

Italian

Italian

Finnish

Finnish

Arabic

Arabic

Danish

Danish

Bulgarian

Bulgarian

Thai

Thai

Polish

Polish

Swedish

Swedish

Greek

Greek

Portuguese

Portuguese

Dutch

Dutch

Spanish

Spanish

Turkish

Turkish

Russian

Russian

Deutsch

Deutsch

French

French

Korean

Korean

Japanese

Japanese

English

English

Leave A Comment