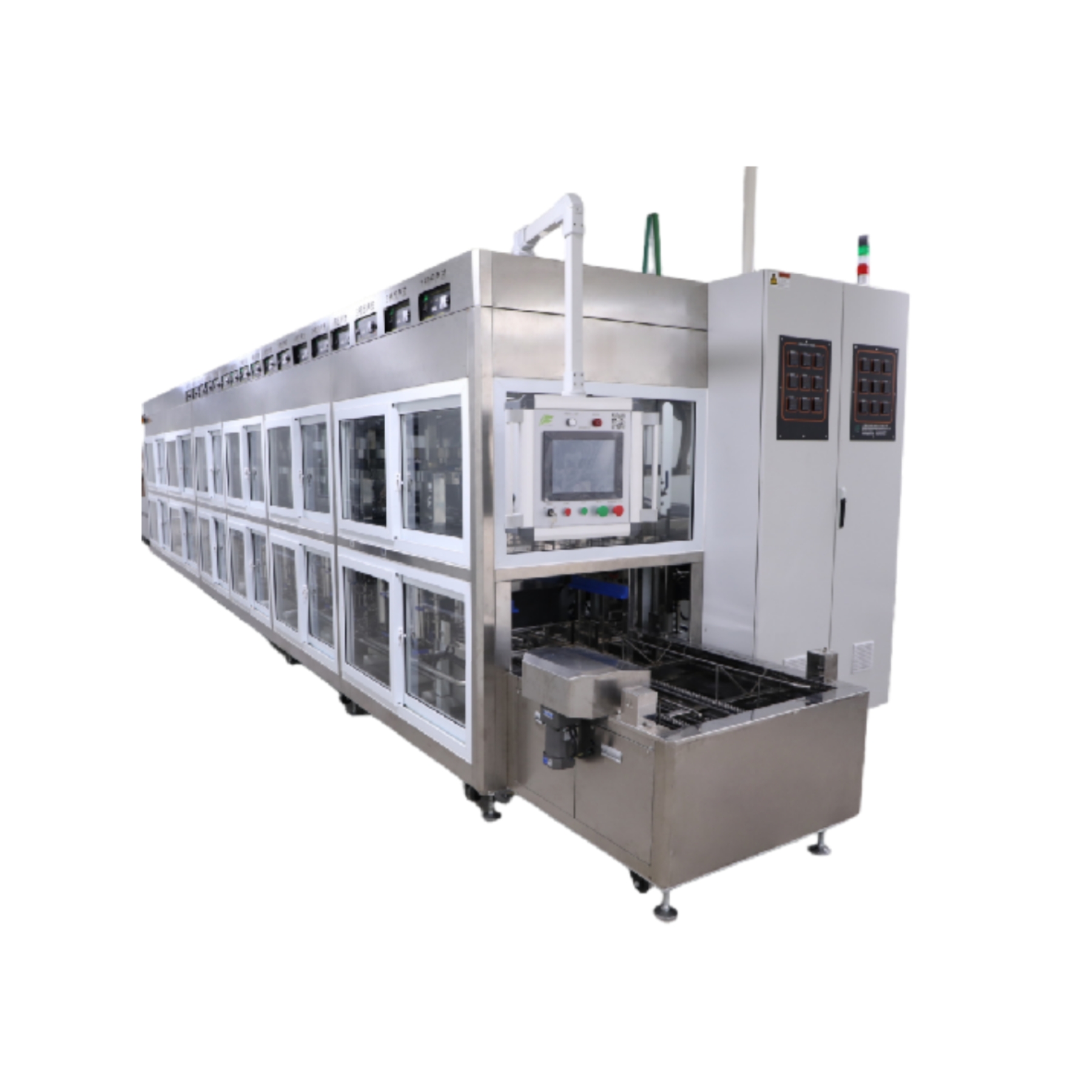

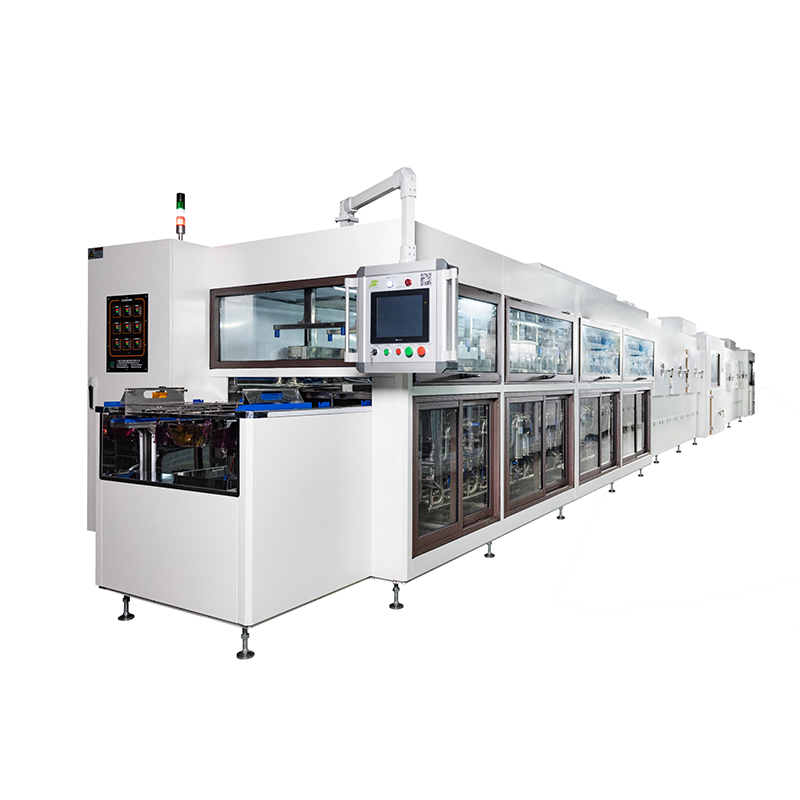

Product Introduction

Fully automatic high-pressure cleaning machine is an industrial-grade cleaning equipment integrating a high-pressure jet system, an intelligent control system, and an automatic walking/positioning mechanism. By pressurizing water (or water-based cleaning agents) to a high-pressure state, it forms a high-speed jet to impact the surface of the workpiece, achieving rapid removal of contaminants such as oil stains, rust, dust, and scale. The equipment supports full-process automated operation and is suitable for batch cleaning scenarios such as large workpieces, production lines, and warehousing facilities. It is widely used in manufacturing, construction, transportation and other industries.

Cleaning parts: engine block, casing, etc

- It adopts a touch screen terminal display, allowing for the selection and setting of various functional parameters. The entire cleaning process is controlled by PLC programmable control, enabling fully automatic operation. It can also be operated manually.

- The transfer between each workstation adopts a mechanical rotation method. The workpiece remains self-rotating during cleaning to avoid cleaning dead corners. The spray pressure can reach 1.2Mpa.

- The demisting method is adopted by freezing.

- Work cycle :120 seconds per piece

Core advantage

1. High-pressure and highly efficient decontamination: The working pressure can reach 100-350MPa, and the jet speed is ≥300m/s. Compared with traditional methods, the cleaning efficiency for stubborn stains (such as carbon deposits on heavy machinery and rust on equipment surfaces) is increased by 400%-600%.

2. Fully automated operation: Equipped with a PLC control system and an automatic walking mechanism, it supports preset cleaning paths, pressure regulation, and flow control. Combined with an infrared positioning/visual recognition module, it enables unmanned operation.

3. Flexible adaptability to scenarios: Supports multiple spraying modes such as high-pressure direct injection, fan-shaped spraying, and rotary spraying. Equipped with extendable and adjustable nozzles, it is suitable for cleaning flat, curved, and complex-structured workpieces.

4. Energy-saving and environmental protection design: It adopts a variable frequency high-pressure pump to adjust the output pressure and flow rate as needed. The water-saving rate is 30%-50% higher than that of ordinary cleaning equipment. An optional cleaning agent recovery system can be equipped to reduce the cost of consumables.

5. Safe, stable and reliable: It integrates multiple safety devices such as high-pressure overload protection, water shortage protection, leakage protection and splash protection. Key components (high-pressure pump, sealing parts, motor) are made of industrial-grade materials, and the average mean time between failures (MTBF) is ≥6000 hours.

This equipment can be designed, developed and manufactured according to different product specifications and production capacities.

Slovenian

Slovenian

Slovak

Slovak

Latvian

Latvian

Bosnian

Bosnian

Icelandic

Icelandic

Ukrainian

Ukrainian

Georgian

Georgian

Serbian

Serbian

Croatian

Croatian

Belarusian

Belarusian

Romanian

Romanian

Estonian

Estonian

Hungarian

Hungarian

Czech

Czech

Catalan

Catalan

Norwegian

Norwegian

Lithuanian

Lithuanian

Albanian

Albanian

Hindi

Hindi

Italian

Italian

Finnish

Finnish

Arabic

Arabic

Danish

Danish

Bulgarian

Bulgarian

Thai

Thai

Polish

Polish

Swedish

Swedish

Greek

Greek

Portuguese

Portuguese

Dutch

Dutch

Spanish

Spanish

Turkish

Turkish

Russian

Russian

Deutsch

Deutsch

French

French

Korean

Korean

Japanese

Japanese

English

English

Leave A Comment