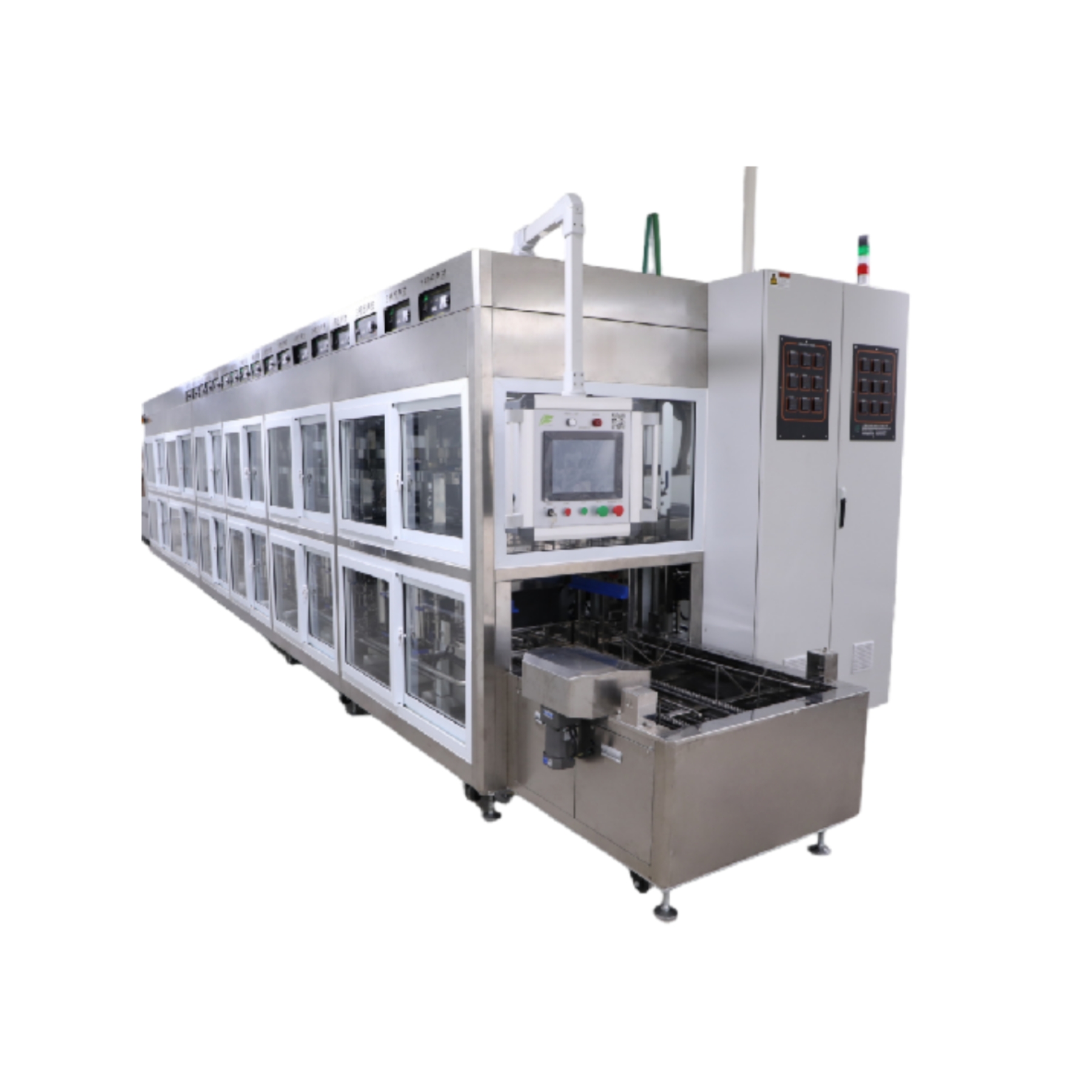

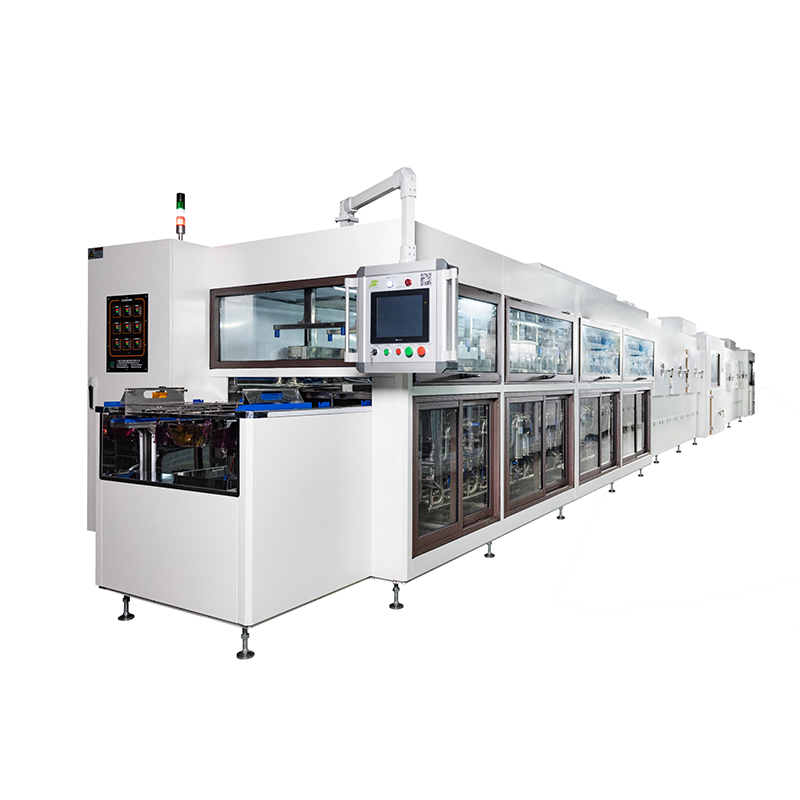

Product Introduction

The fully automatic multi-arm cleaning machine is a high-end industrial cleaning equipment integrating multi-axis mechanical arm handling, multi-tank grading cleaning and intelligent closed-loop control. Adopting PLC programmable control system and servo drive technology, combined with environmentally friendly hydrocarbon solvents and multi-dimensional cleaning processes, it realizes the full-process automated operation from workpiece loading, cleaning, drying to unloading, providing efficient, consistent and residue-free cleaning services for precision parts in batch production scenarios.

Cleaning parts: pistons, valve bodies, etc

- The equipment adopts a fully enclosed structure with a novel appearance. It is highly operable and has a strong sense of integrity. The color can be customized by the customer. The equipment has abnormal sound and light alarms. Handle the abnormalities according to the alarm prompts, reducing the skill requirements for the operators.

- The equipment is equipped with a multi-stage circulation filtration system to ensure the cleanliness of the solution, extend the service life, reduce production costs, and at the same time improve the cleaning cleanliness of the product.

- The cleaning tank is made of high-quality stainless steel sus304 plate, which is corrosion-resistant, does not rust and has a long service life

- The filtration system is easy to replace and can be reused after multiple cleanings, with low replacement costs.

- It adopts a PLC+ human-machine interface control system, featuring high degree of automation, simple operation and flexible software upgrade.

Core advantage

1. Full-process automation: Equipped with 3-6 axis servo mechanical arms, with a repeat positioning accuracy of ±0.05mm, it automatically completes the transfer of workpieces among multiple tanks without manual intervention, significantly enhancing production efficiency (production capacity is increased by 300%-500% compared to semi-automatic equipment).

2. Multi-station staged cleaning: Equipped with multi-stage tanks such as pre-washing, main washing, rinsing, and drying, combined with composite cleaning methods like ultrasonic, vacuum, and polishing, it achieves a stepwise processing of "coarse dirt removal → precise cleaning → deep drying", with a cleaning qualification rate of ≥99.8%.

3. Intelligent and precise control: Equipped with a 7-inch touch screen and PLC control system, it supports the storage of over 100 cleaning programs, can monitor equipment operation parameters (temperature, vacuum degree, solvent purity, etc.) in real time, and supports data traceability and remote diagnosis.

4. Safety and environmental protection upgrade: Enhanced explosion-proof design (explosion-proof grade Exd II BT4), equipped with an intelligent solvent regeneration system and VOCs recovery device, solvent recovery rate over 99.98%, meeting strict environmental protection standards;

5. Stable, reliable and durable: The robotic arm is made of industrial-grade high-strength materials, and the tank body is selected from 316L stainless steel. Key components (vacuum pump, ultrasonic generator) are all from first-line brands, with an average mean time between failures (MTBF) of ≥8000 hours.

This equipment can be designed, developed and manufactured according to different product specifications and production capacities.

Slovenian

Slovenian

Slovak

Slovak

Latvian

Latvian

Bosnian

Bosnian

Icelandic

Icelandic

Ukrainian

Ukrainian

Georgian

Georgian

Serbian

Serbian

Croatian

Croatian

Belarusian

Belarusian

Romanian

Romanian

Estonian

Estonian

Hungarian

Hungarian

Czech

Czech

Catalan

Catalan

Norwegian

Norwegian

Lithuanian

Lithuanian

Albanian

Albanian

Hindi

Hindi

Italian

Italian

Finnish

Finnish

Arabic

Arabic

Danish

Danish

Bulgarian

Bulgarian

Thai

Thai

Polish

Polish

Swedish

Swedish

Greek

Greek

Portuguese

Portuguese

Dutch

Dutch

Spanish

Spanish

Turkish

Turkish

Russian

Russian

Deutsch

Deutsch

French

French

Korean

Korean

Japanese

Japanese

English

English

Leave A Comment