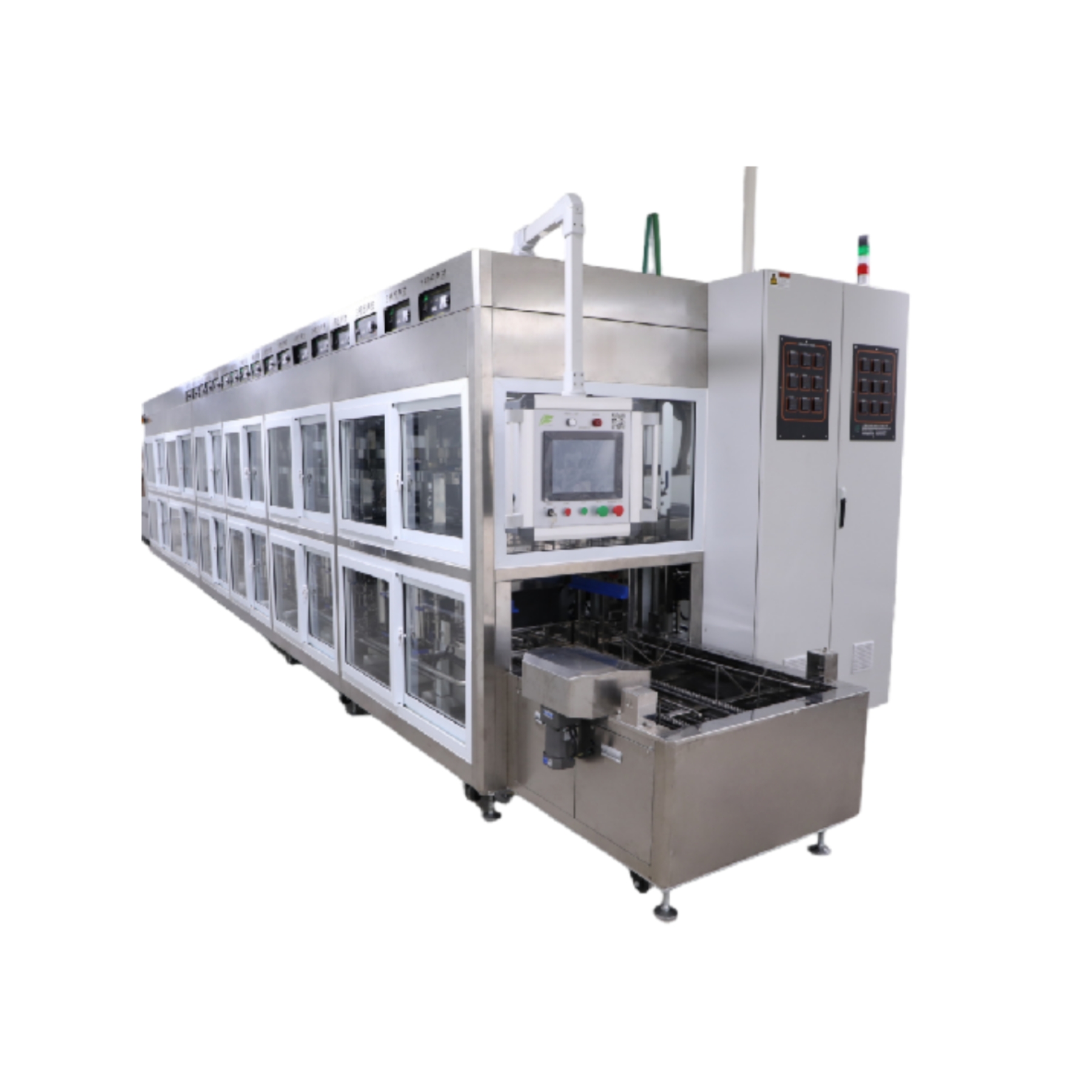

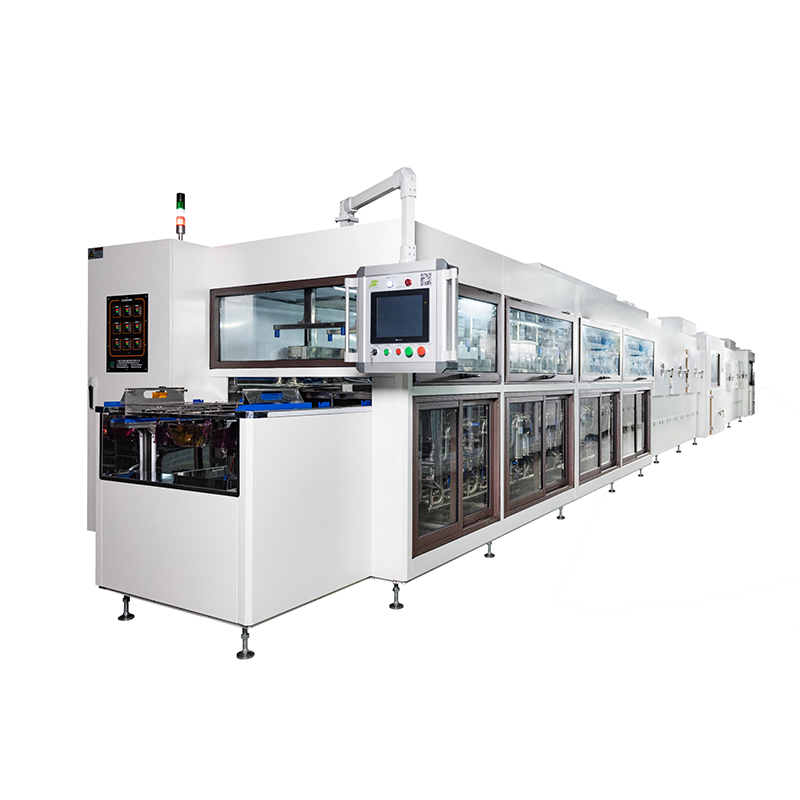

Product Introduction

The fully automatic solvent cleaning machine is a dedicated cleaning device specially developed for precision hardware parts, electronic components, automotive parts, aerospace components, medical devices, etc. It integrates the full-process automated functions of "solvent immersion + ultrasonic cleaning + vacuum degassing + steam rinsing + vacuum drying + solvent regeneration". Using environmentally friendly solvents (hydrocarbons/halogenated hydrocarbons/alcohols) as cleaning media, it targets organic contaminants such as oil stains, grease, resin, and flux on the surface of workpieces. Through the "like dissolves like" principle and multi-dimensional cleaning processes, it achieves efficient and residue-free decontamination, making it suitable for batch production scenarios with strict cleanliness requirements.

- Cleaning parts: brakes, brake shoes, oil pipes, precision hardware, bearings, etc

- The equipment is of a fully enclosed structure, with a novel appearance, and is highly operable and has a strong sense of integrity

- The equipment has abnormal sound and light alarms. Handle the abnormalities according to the alarm prompts to reduce the skill requirements for the operators.

- It adopts a PLC+ human-machine interface control system, featuring high degree of automation, simple operation and flexible software upgrade.

- The equipment adopts a centrifugal spin-drying process, effectively and evenly protecting the surface oil film, ensuring that the packaged products do not drip oil

- The equipment is made of all high-quality stainless steel sus304 plates, which are corrosion-resistant, do not rust and have a long service life

- The air conditioning unit adopts the French "Tecumseh" low-temperature unit, which is suitable for long-term operation under harsh working conditions, featuring excellent cooling effect and high energy efficiency ratio

- The equipment is equipped with a multi-stage circulation filtration system to ensure the cleanliness of the solution, extend the service life, reduce production costs, and at the same time improve the cleaning cleanliness of the product. The filtration system adopts a stainless steel double parallel filter, equipped with a wound stainless steel frame filter element inside, which is easy to replace and has a low replacement cost.

- The cleaning time can be set and adjusted by the customer according to the difficulty of cleaning the workpiece.

- The cleaning tank is equipped with a stainless steel cover, which can reduce noise when the equipment is in use and prevent dust from falling into the tank and contaminating the solvent when the equipment is not in use

- The equipment is equipped with an independent distillation regeneration and recovery system, enabling the cleaning tank to continuously replenish new liquid and enhance the cleanliness of the workpieces. Moreover, the solvent can be reused. Only a small amount of liquid needs to be added, which greatly reduces the usage cost

- The unique design of the oil removal mechanism for the liquid surface of the cleaning tank prevents the secondary contamination of the workpiece by the dirty oil on the liquid surface

- Work pace :5-8 minutes per basket

Core advantages (Exclusive features for solvent cleaning)

1. Multi-solvent compatibility and adaptation: Supports various environmentally friendly solvents such as hydrocarbon solvents (alkanes/cycloalkanes), halogenated hydrocarbons (trichloroethylene/tetrachloroethylene), alcohols (isopropanol/ethanol), etc. Flexible selection can be made based on the material of the workpiece and the type of contaminants.

2. Deep and thorough cleaning without blind spots: Vacuum degassing breaks through the "air resistance" in deep holes, blind holes and threads of workpieces. Combined with 28/40/68kHz multi-frequency ultrasonic waves, it thoroughly removes contaminants from minute crevices, achieving a cleanliness level of ISO 16232-10.

3. Explosion-proof safety design: The explosion-proof grade of the entire machine is Exd II BT4, integrating flammable gas concentration monitoring (alarm threshold ≤10% LEL), explosion-proof motor, automatic fire extinguishing device, and vacuum hypoxia protection, effectively avoiding the risk of solvent flammability from the source.

4. Solvent recycling and regeneration: Built-in vacuum distillation regeneration system + multi-stage filtration, solvent recovery rate ≥99.95%, loss rate ≤0.05%, significantly reducing usage costs and meeting environmental protection emission requirements;

5. Full-process automation: PLC programmable control, supports storage of over 80 cleaning schemes, automatically completes the entire process from feeding, cleaning, rinsing, drying, discharging to solvent regeneration without manual intervention, and increases production capacity by 400% compared to semi-automatic equipment.

This equipment can be designed, developed and manufactured according to different product specifications and production capacities.

Slovenian

Slovenian

Slovak

Slovak

Latvian

Latvian

Bosnian

Bosnian

Icelandic

Icelandic

Ukrainian

Ukrainian

Georgian

Georgian

Serbian

Serbian

Croatian

Croatian

Belarusian

Belarusian

Romanian

Romanian

Estonian

Estonian

Hungarian

Hungarian

Czech

Czech

Catalan

Catalan

Norwegian

Norwegian

Lithuanian

Lithuanian

Albanian

Albanian

Hindi

Hindi

Italian

Italian

Finnish

Finnish

Arabic

Arabic

Danish

Danish

Bulgarian

Bulgarian

Thai

Thai

Polish

Polish

Swedish

Swedish

Greek

Greek

Portuguese

Portuguese

Dutch

Dutch

Spanish

Spanish

Turkish

Turkish

Russian

Russian

Deutsch

Deutsch

French

French

Korean

Korean

Japanese

Japanese

English

English

Leave A Comment