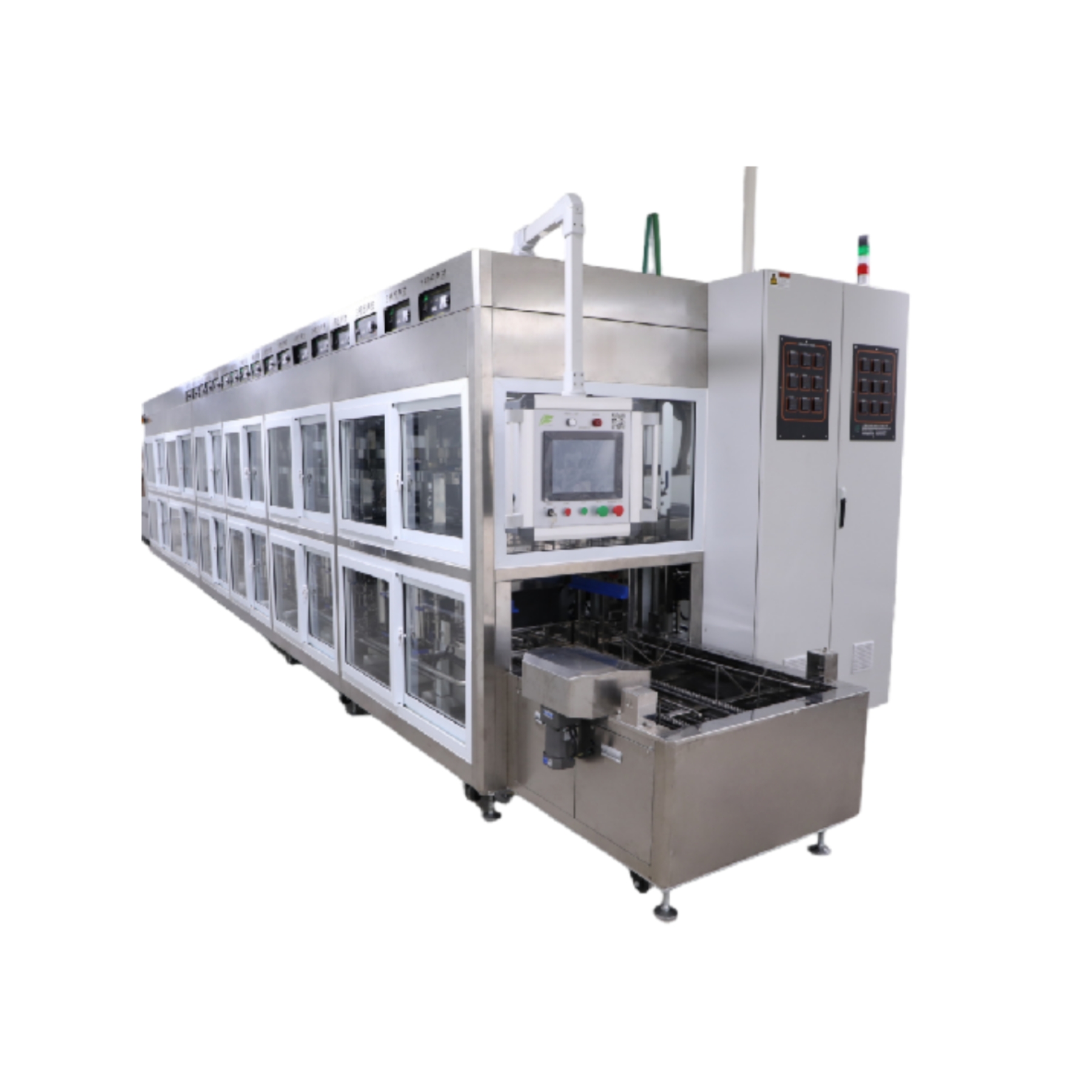

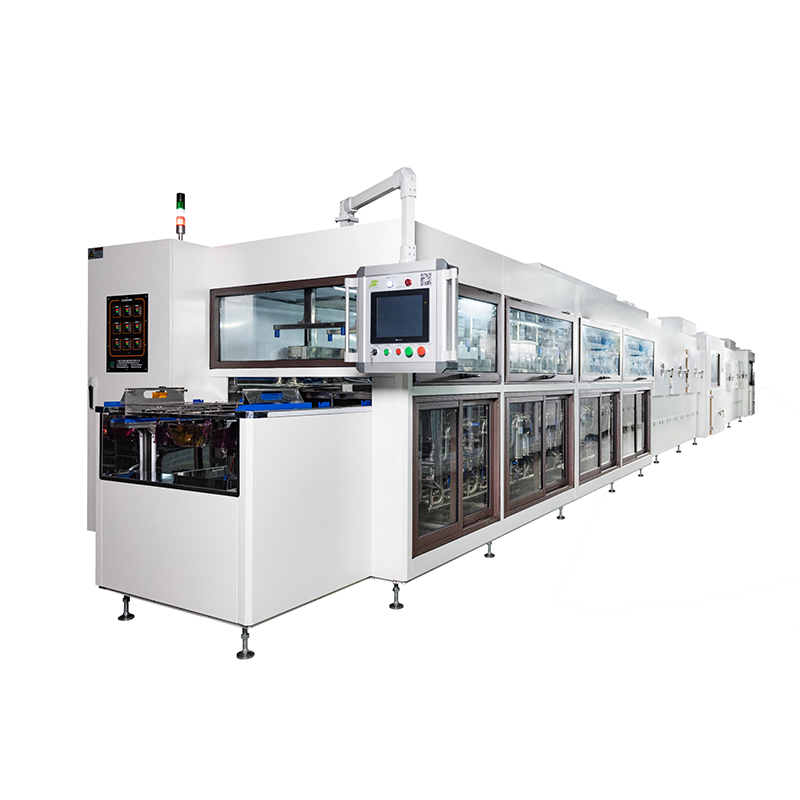

Hard Removal and Demold Machine

Product Introduction

Hard Removal and Demold Machine is used for the processing of hardened and coated reworked lenses. It is a professional device specially designed for the production, processing, rework and repair of optical lenses (such as resin lenses and glass lenses). It is mainly used to remove the hardened film (hardening film), anti-reflection film, reflective film and other functional film layers on the surface of the lenses. Its core value lies in solving the problem of lens scrapping caused by coating defects (such as scratches, bubbles, color differences), deviations in process parameters or changes in customer customization requirements during lens production. Through efficient and precise film removal treatment, it realizes the secondary utilization of lens substrate, significantly reduces production costs, and at the same time ensures that the lens substrate is not damaged during the treatment process. Maintain the original optical performance and surface flatness.

This equipment is widely used in optical lens manufacturing enterprises, eyewear processing factories and optical component repair institutions. It is one of the key devices in the optical lens industry chain for improving resource utilization and optimizing production processes.

Main features

- Dual-process integrated design: It integrates the functions of "hardening" and "film removal". According to the type of lens film layer (hardening film + functional film), you can choose to remove the film alone or the composite process of hardening first and then removing the film. There is no need to replace equipment or make complicated adjustments, and the operation is convenient and efficient.

- Precise temperature control and time adjustment: Equipped with an intelligent temperature control system, the temperature adjustment range is 20-120℃, with a temperature control accuracy of ±1℃. The optimal processing temperature can be set according to different film layer materials (such as silicone hardening film, silicon oxide anti-reflection film). It also supports a time setting of 0 to 999 minutes to ensure thorough removal of the film layer without damaging the lens substrate.

- Environmentally friendly treatment solution: Equipped with a dedicated environmentally friendly film release agent circulation system, using low-volatile and low-corrosive environmentally friendly chemical reagents to reduce pollution to the environment. The circulating filtration device can purify and recover the demolding agent, extend the service life of the reagent and reduce the cost of consumables.

- Multi-specification compatibility: Supports lens diameters ranging from Φ20 to Φ150mm, capable of handling various types of optical lenses such as single vision lenses, progressive multifocal lenses, and prism lenses, meeting the demands of different production scenarios.

- Automation and Safety: It adopts a PLC control system, equipped with a 7-inch touch screen operation interface, supporting process parameter storage (capable of storing 50 sets of process formulas), one-click start and automatic fault alarm functions. The equipment is equipped with safety devices such as anti-leakage protection, over-temperature protection, and emergency stop buttons to ensure the safety of operators and the equipment.

- High-efficiency and uniform processing: It adopts a rotating lens frame design. During the processing, the lenses rotate at a constant speed to ensure full contact between the film layer and the film release agent. The uniformity of film release is over 99%, avoiding local residue or excessive corrosion.

Product specification

| Product Model | SFT-M | SFT-A |

Machine Size (mm)L*W*H | 2300mm*1450mm*1900mm | 3500mm*2100mm*2300mm |

Voltage and Frequency(V/HZ) | 380V/50HZ | 380V/50HZ |

| Material | PVC/PP | PVC/PP |

| Medium | Ammonium hydrogen fluoride/alkali | Ammonium hydrogen fluoride/alkali |

Power | 30KW | 35KW |

Machine Weight | 500KG | 900KG |

This equipment can be designed, developed, produced and manufactured according to different product specifications.

back

Slovenian

Slovenian

Slovak

Slovak

Latvian

Latvian

Bosnian

Bosnian

Icelandic

Icelandic

Ukrainian

Ukrainian

Georgian

Georgian

Serbian

Serbian

Croatian

Croatian

Belarusian

Belarusian

Romanian

Romanian

Estonian

Estonian

Hungarian

Hungarian

Czech

Czech

Catalan

Catalan

Norwegian

Norwegian

Lithuanian

Lithuanian

Albanian

Albanian

Hindi

Hindi

Italian

Italian

Finnish

Finnish

Arabic

Arabic

Danish

Danish

Bulgarian

Bulgarian

Thai

Thai

Polish

Polish

Swedish

Swedish

Greek

Greek

Portuguese

Portuguese

Dutch

Dutch

Spanish

Spanish

Turkish

Turkish

Russian

Russian

Deutsch

Deutsch

French

French

Korean

Korean

Japanese

Japanese

English

English

Leave A Comment