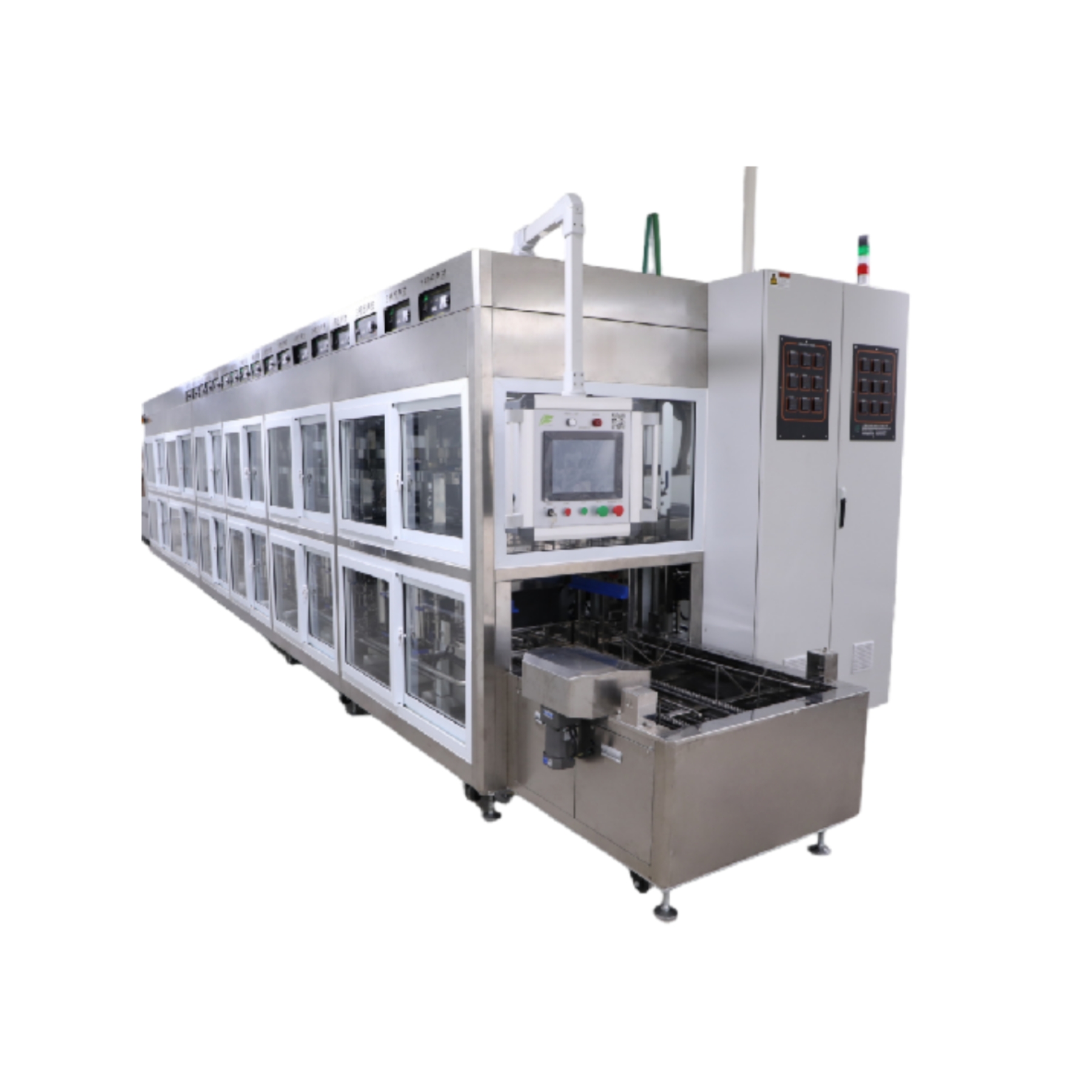

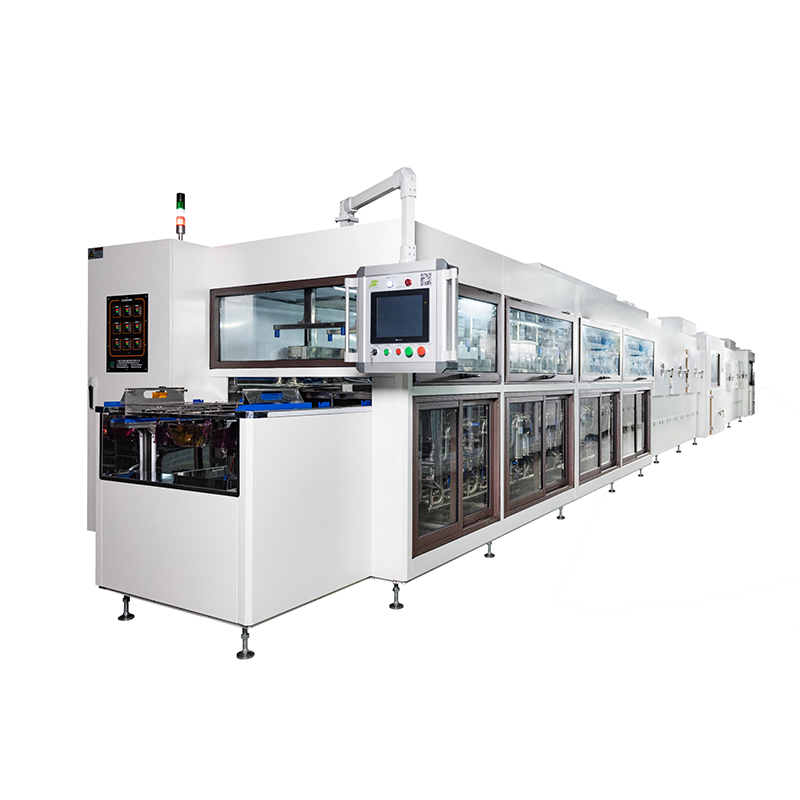

Mold storage table

Product Introduction

The mold storage table is a dedicated workbench specifically designed for the storage, classification and management of molds after film closing, featuring dust-proof functionality. The mold storage table is a precision mold storage and management device specially designed for the optical industry. It is mainly used to store high-precision molds required for the production of optical glass lenses, resin lenses, etc. Optical lens molds have extremely high requirements for surface finish and dimensional accuracy. Traditional storage methods are prone to mold scrapping due to bumps, dust pollution, humidity changes, etc. This storage table, through customized structural design and precise protection technology, achieves dust-free storage, precise positioning and safety protection of optical lens molds. It is a core equipment for material management in the workshop of optical manufacturing enterprises.

Core features

- Precise load-bearing control, compatible with lens molds: It adopts a combination of high-strength aviation aluminum alloy frame and tempered glass layer plates. The frame thickness is 2.0mm and the layer plate thickness is 12mm. After anodic oxidation treatment, the load-bearing is uniform and stable. The load-bearing capacity of a single layer plate is precisely controlled within 50-200kg, which not only meets the storage requirements of optical lens molds (typically weighing 5-50kg), but also avoids the structural bulkiness caused by excessive load-bearing. Meanwhile, the tempered glass layer plate has good light transmission, making it convenient to observe the storage status of the molds.

- Layered fine-tuning design, precisely adapted to mold size: The height of the layer plate adopts a rack and pinion fine-tuning structure, with the adjustment spacing fine to 10mm, which can be precisely adapted to the height of optical lens molds of different specifications (diameter 20mm-300mm). The layer plates are fixed by magnetic attraction. The adjustment process is smooth and vibration-free, avoiding the displacement or collision of the mold due to vibration and ensuring the precise storage position of the mold.

- Dust-free protection structure, ensuring mold cleanliness: Equipped with a transparent dust cover and an internal dehumidification device. The dust cover is made of acrylic material with a light transmittance of 92%, effectively isolating workshop dust. The dehumidification device monitors the humidity inside the chamber in real time, keeping it at 40%-60%RH to prevent the surface of the optical lens mold from getting damp and oxidized. Silicone anti-slip pads are laid on the surface of the layer board. The hardness of the silicone is 30°, which can not only fix the mold but also prevent the surface of the mold from being scratched.

- Anti-corrosion surface treatment, extending equipment service life: The frame is treated with anodic oxidation, with an oxide film thickness of up to 15μm, which has excellent anti-corrosion and anti-scratch performance. The surface of the dust cover is sprayed with an anti-fingerprint coating, which is easy to clean. The overall structure can withstand the corrosion of common cleaning reagents such as alcohol and isopropyl alcohol in optical workshops, and is suitable for the clean production environment of the optical industry.

- Intelligent identification management, enhancing retrieval efficiency: The edge of the layer board integrates electronic tag card slots and LED indicator lights. Mold information can be bound by scanning a code, and the system automatically records the storage location of the mold. When taking out the mold, the LED light at the corresponding position lights up to achieve rapid positioning. It is also equipped with a drawer-type tool box for storing auxiliary tools such as mold cleaning cloths and gloves, facilitating cleaning and maintenance before and after taking out the molds.

Product Specification

| Product Model | SFCF-01 |

Machine Size(mm)L*W*H | 1600mm*750mm*1800mm |

Voltage and Frequency(V/HZ) | 220V/50HZ |

| Power | 200W |

| Machine Weight | 80KG |

This equipment can be designed, developed and manufactured according to different product specifications and production capacities.

back

Slovenian

Slovenian

Slovak

Slovak

Latvian

Latvian

Bosnian

Bosnian

Icelandic

Icelandic

Ukrainian

Ukrainian

Georgian

Georgian

Serbian

Serbian

Croatian

Croatian

Belarusian

Belarusian

Romanian

Romanian

Estonian

Estonian

Hungarian

Hungarian

Czech

Czech

Catalan

Catalan

Norwegian

Norwegian

Lithuanian

Lithuanian

Albanian

Albanian

Hindi

Hindi

Italian

Italian

Finnish

Finnish

Arabic

Arabic

Danish

Danish

Bulgarian

Bulgarian

Thai

Thai

Polish

Polish

Swedish

Swedish

Greek

Greek

Portuguese

Portuguese

Dutch

Dutch

Spanish

Spanish

Turkish

Turkish

Russian

Russian

Deutsch

Deutsch

French

French

Korean

Korean

Japanese

Japanese

English

English

Leave A Comment