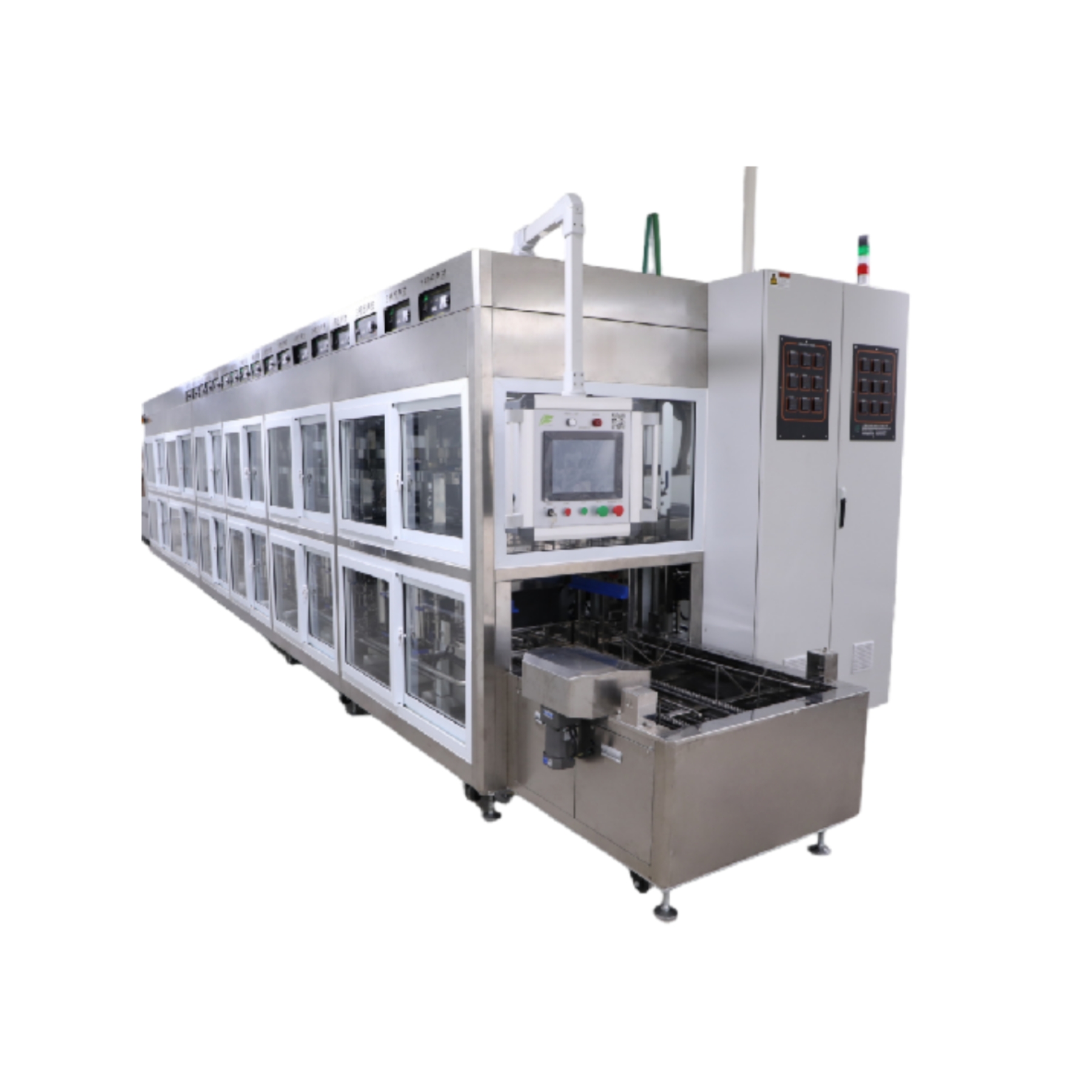

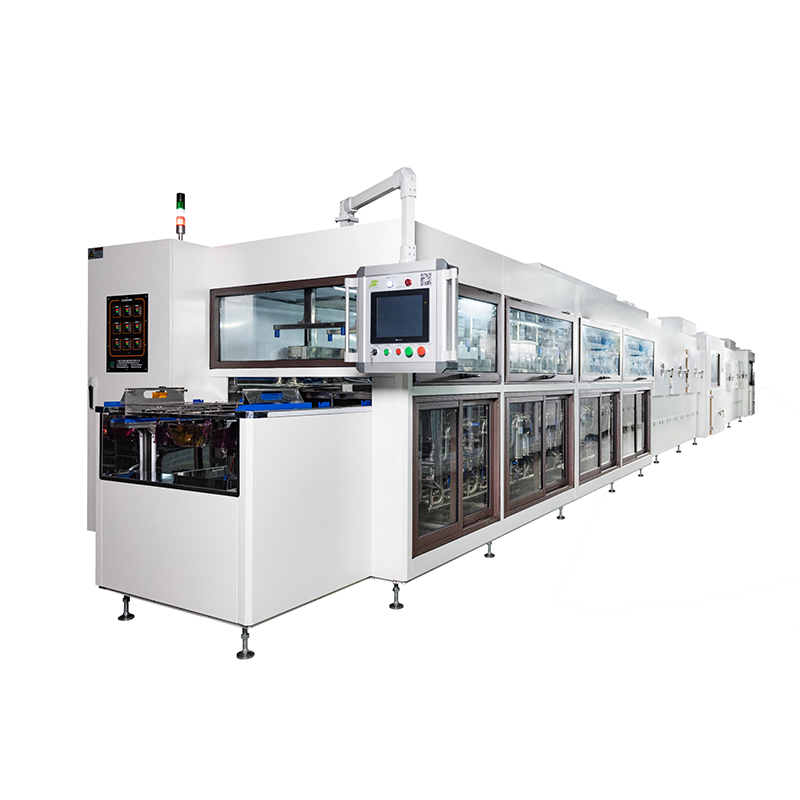

Product Introduction

The plasma cleaning machine generates plasma through glow discharge. The high-energy electrons, ions, free radicals and other active particles in it can physically collide or chemically react with contaminants, decomposing the contaminants into volatile gases (such as CO₂, H₂O, etc.) and discharging them through a vacuum pump, thereby achieving efficient cleaning of the surface of optical components.

Atmospheric pressure: The plasma surface treatment machine is composed of a plasma generator, gas delivery pipelines and plasma nozzles, etc. The plasma generator generates high-voltage and high-frequency energy, which is activated and controlled in the glow discharge of the nozzle steel pipe to produce low-temperature plasma. The particle energy in plasma is generally several to tens of electron volts, which is greater than the bonding energy of polymer materials and can completely break the chemical bonds of organic macromolecules to form new bonds. However, it is far lower than that of high-energy radioactive rays, only involving the surface of the material and not affecting the performance of the matrix. In a low-temperature plasma in a non-thermodynamic equilibrium state, electrons have relatively high energy, which can break the chemical bonds of molecules on the material surface and enhance the chemical reactivity of particles (greater than that in thermal plasma), while the temperature of neutral particles is close to room temperature. These advantages provide suitable conditions for the surface modification of heat-sensitive polymer materials.

Low voltage: The device for generating plasma in a plasma cleaning/etching machine is to set up two electrodes in a sealed container to form an electric field, and a vacuum pump is used to achieve a certain degree of vacuum. As the gas becomes increasingly thin, the distance between molecules and the free movement distance of molecules or ions also increase. Under the influence of an electric field, they collide to form plasma. These ions are highly reactive and their energy is sufficient to break almost all chemical bonds and cause chemical reactions on any exposed surface. Plasmas of different gases have different chemical properties. For instance, plasma of oxygen has a very high oxidizing property, which can oxidize the photoresist reaction and generate gas, thereby achieving the cleaning effect. The plasma of corrosive gases has excellent anisotropy, which can meet the requirements of etching. When plasma treatment is carried out, it emits glow, so it is called glow discharge treatment.

Applicable scenarios

Optical industry: Removal of oil stains and fingerprints from optical lenses and lenses to prevent surface scratches caused by traditional cleaning methods;

Electronic manufacturing: Surface activation of PCB circuit boards, removal of flux residues, and precise cleaning before semiconductor chip packaging;

Medical devices: Sterilization and surface modification of surgical instruments and implants (such as artificial joints) to enhance biocompatibility;

Automotive industry: Surface cleaning and activation of automotive lamps, sensors and other components, enhancing coating adhesion;

In the field of new materials: Surface treatment of polymer materials and composite materials to improve their bonding and printing properties;

Packaging industry: Surface activation of packaging materials such as plastic films and metal foils to enhance the fastness of printing or lamination

Product Specification

| Product Model | SF-XSL | SF-XSM |

Machine Size (mm)L*W*H | 1600mm*2100mm *1750mm | 800mm*1600mm *1700mm |

Internal cavity volume | 200-2000L | 20-200L |

| Plasma output power | 0-20KW/Adjustable | 0-10KW/Adjustable |

Power supply operating frequency | 40KHZ/13.56MHZ | 40KHZ/13.56MHZ |

| Discharge vacuum degree | 30-500Mterr | 30-500Mterr |

| Machine weight | 3000KG | 1500KG |

This equipment can be designed, developed and manufactured according to different product specifications and production capacities.

Slovenian

Slovenian

Slovak

Slovak

Latvian

Latvian

Bosnian

Bosnian

Icelandic

Icelandic

Ukrainian

Ukrainian

Georgian

Georgian

Serbian

Serbian

Croatian

Croatian

Belarusian

Belarusian

Romanian

Romanian

Estonian

Estonian

Hungarian

Hungarian

Czech

Czech

Catalan

Catalan

Norwegian

Norwegian

Lithuanian

Lithuanian

Albanian

Albanian

Hindi

Hindi

Italian

Italian

Finnish

Finnish

Arabic

Arabic

Danish

Danish

Bulgarian

Bulgarian

Thai

Thai

Polish

Polish

Swedish

Swedish

Greek

Greek

Portuguese

Portuguese

Dutch

Dutch

Spanish

Spanish

Turkish

Turkish

Russian

Russian

Deutsch

Deutsch

French

French

Korean

Korean

Japanese

Japanese

English

English

Leave A Comment