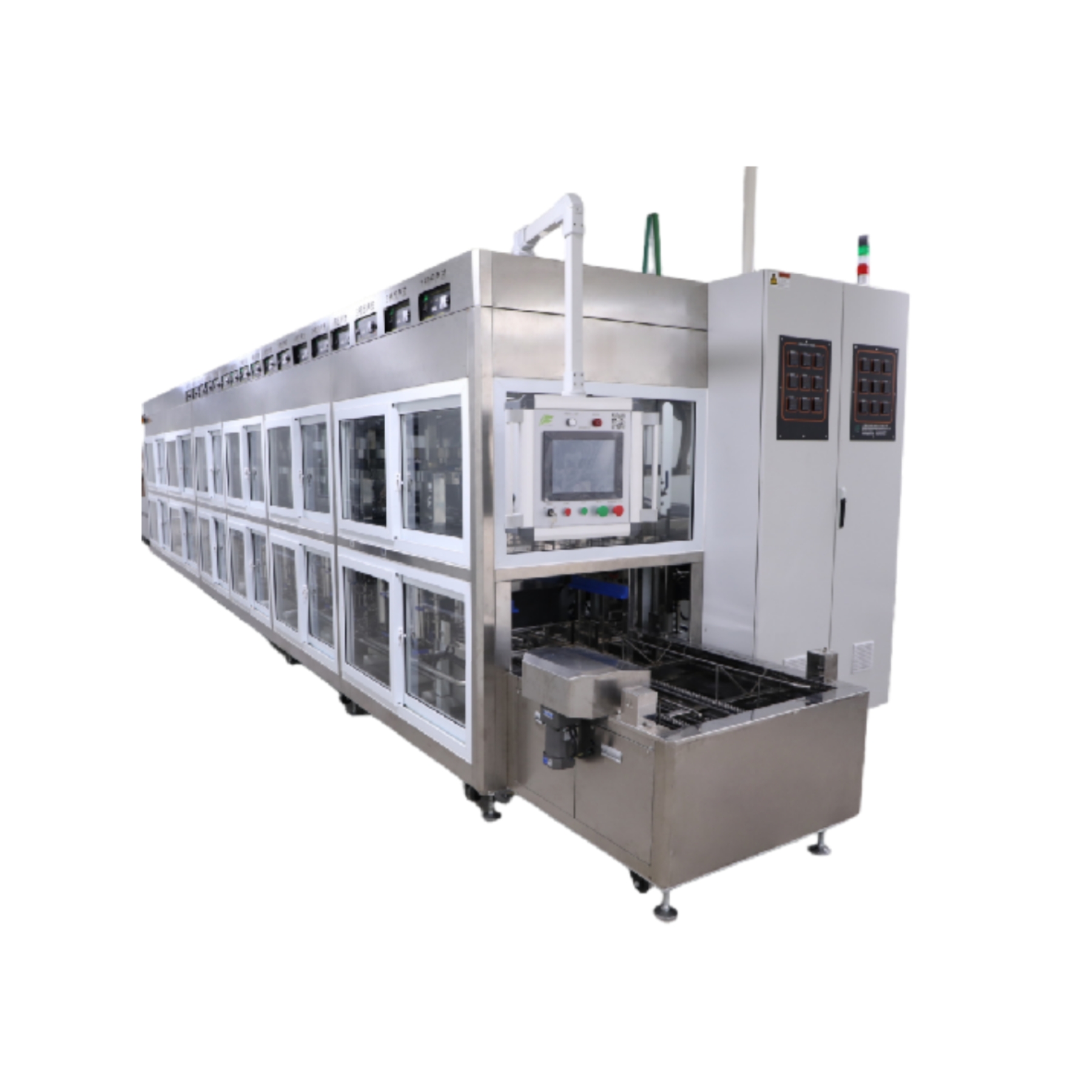

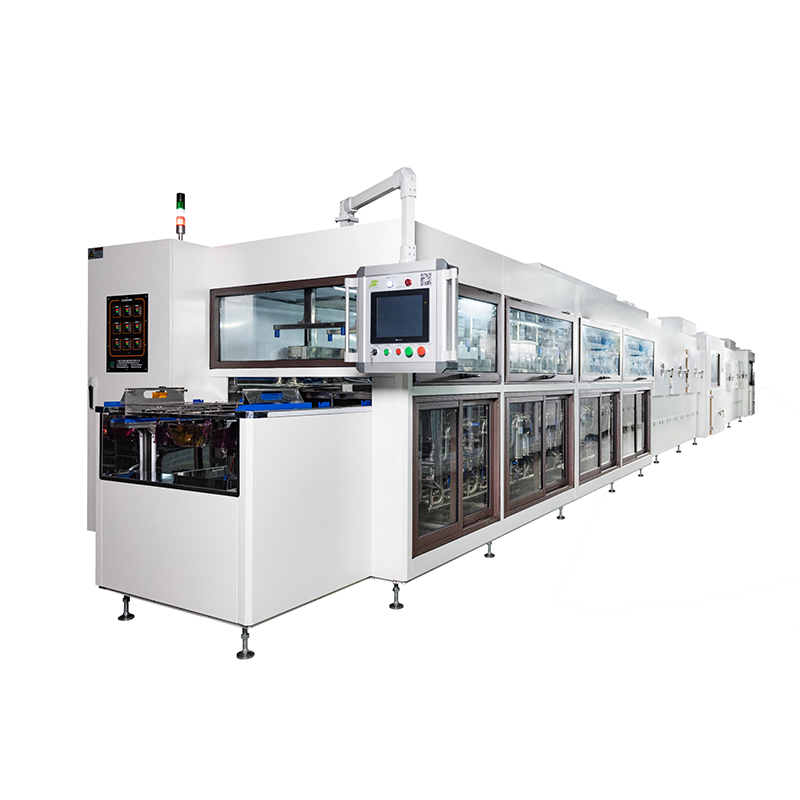

Product Introduction

The rotary dehumidifier is a professional device that adopts adsorption dehumidification technology. Through specially treated silica gel/molecular sieve rotors, it efficiently removes moisture from the air. It is widely applied in fields with strict requirements for humidity control, such as optical lenses, pharmaceutical storage, and precision electronics.

This product is the ZHS-5000Q-B2 type rotor dehumidifier, with a rated air processing capacity of 5000 m ³ /h. The regeneration method adopts steam heating, and the rotor specification is Φ900*200 mm. It is suitable for environments with high requirements for air humidity to precisely control the high-process environment needed for production and manufacturing. This dehumidifier, in combination with our company's system process design and efficient and reasonable control combination, can economically and effectively ensure the production conditions of the process.

1.1 Box Body

The ZHS-Q dehumidifier adopts a frame structure and is installed according to the processing and control requirements. The panel is double-layered, with color steel plate on the outside and galvanized steel plate on the inside. It is filled with insulation cotton and sealed with anti-corrosion sealing strips. The base is made of steel profiles and is equipped with forklift holes, which is convenient for forklift hoisting during transportation and installation. All areas are equipped with access doors, and spacious access passages facilitate maintenance and repair.

1.2 Runner and runner frame

The rotor is the most crucial component of a dehumidifier unit, and its quality directly affects the performance and characteristics of the dehumidifier unit. Our company exclusively uses imported Puworth rotors from abroad to ensure the efficiency and functionality of our dehumidifiers. Meet the needs of customers.

1.3 Air handling section

The air outlet filter screen adopts a pull-out type, which not only ensures the filtration efficiency but also makes replacement convenient. The fan has a compact structure, is elegant and generous, and is easy to install. This fan features high efficiency, low noise and large air volume.

1.4 Regeneration heating section

It is made of stainless steel and filled with insulation cotton to ensure a constant regeneration heating temperature and the working condition of the rotor to guarantee the efficiency of the dehumidifier.

Working principle

The main structure of a rotary dehumidifier is a constantly rotating honeycomb-shaped rotor. The drying rotor is the most crucial component in a dehumidifier for absorbing moisture. It is composed of corrugated media made of special composite heat-resistant materials, and the corrugated media carry desiccants (such as high-efficiency active silica gel, molecular sieves, etc.). This design is compact in structure and provides a large dehumidification surface. The dehumidification rotor is divided into two zones by partitions containing highly sealed packing: one is a 270° fan-shaped area at the air treatment end; The first is the 90° fan-shaped area at the end of the regenerative air.

When the moist air to be dehumidified (treated air) enters the sector area, the water molecules in the air are absorbed by the desiccant inside the rotor, and the dried air is then sent to the dry air outlet through the treated fan.

During the dehumidification process, the dehumidification rotor rotates slowly and continuously. When the rotor fan surface in the air processing area absorbs water molecules and becomes saturated, it is transferred to the regeneration air end. The regeneration air (usually outdoor air) is heated and uses high-temperature air to carry out the water molecules in the rotor, while the wet air is discharged outdoors by the regeneration fan.

During the process of the rotor dehumidifying and regenerating simultaneously, the air is constantly dehumidified, the rotor is continuously regenerated, and the rotor repeats the dehumidification process at a slow speed in a continuous cycle.

Product Specification

Product Model | SF-1100D |

Machine Size(mm)L*W*H | 1450mm*700mm*1950mm |

Temperature | 20-25°C |

Relative Humidity | 30-45RH(%) |

Voltage and Frequency | 380V/50HZ |

| Power | 16.5KW |

Machine Weight | 800KG |

This equipment can be designed, developed and manufactured according to different product specifications and production capacities.

Slovenian

Slovenian

Slovak

Slovak

Latvian

Latvian

Bosnian

Bosnian

Icelandic

Icelandic

Ukrainian

Ukrainian

Georgian

Georgian

Serbian

Serbian

Croatian

Croatian

Belarusian

Belarusian

Romanian

Romanian

Estonian

Estonian

Hungarian

Hungarian

Czech

Czech

Catalan

Catalan

Norwegian

Norwegian

Lithuanian

Lithuanian

Albanian

Albanian

Hindi

Hindi

Italian

Italian

Finnish

Finnish

Arabic

Arabic

Danish

Danish

Bulgarian

Bulgarian

Thai

Thai

Polish

Polish

Swedish

Swedish

Greek

Greek

Portuguese

Portuguese

Dutch

Dutch

Spanish

Spanish

Turkish

Turkish

Russian

Russian

Deutsch

Deutsch

French

French

Korean

Korean

Japanese

Japanese

English

English

Leave A Comment