- HOME

- PRODUCTS

- Ultrasonic Cleaning Machine

- Plasma cleaning machine

- Lens wiping machine

- rotary dehumidifier

- Oven

- Chiller

- Sand-blasting Machine

- Mixing Tank

- Dust-free Workbench before coating

- Dyeing Machine

- Conveyor

- Pure water equipment

- Solvent Cleaning Machine

- Die stand

- Mold storage table

- Work test bench

- Other accessories

- Single-piece hardening machine

- Hard removal and demold machine

- Semi-automatic hydrocarbon cleaning machine

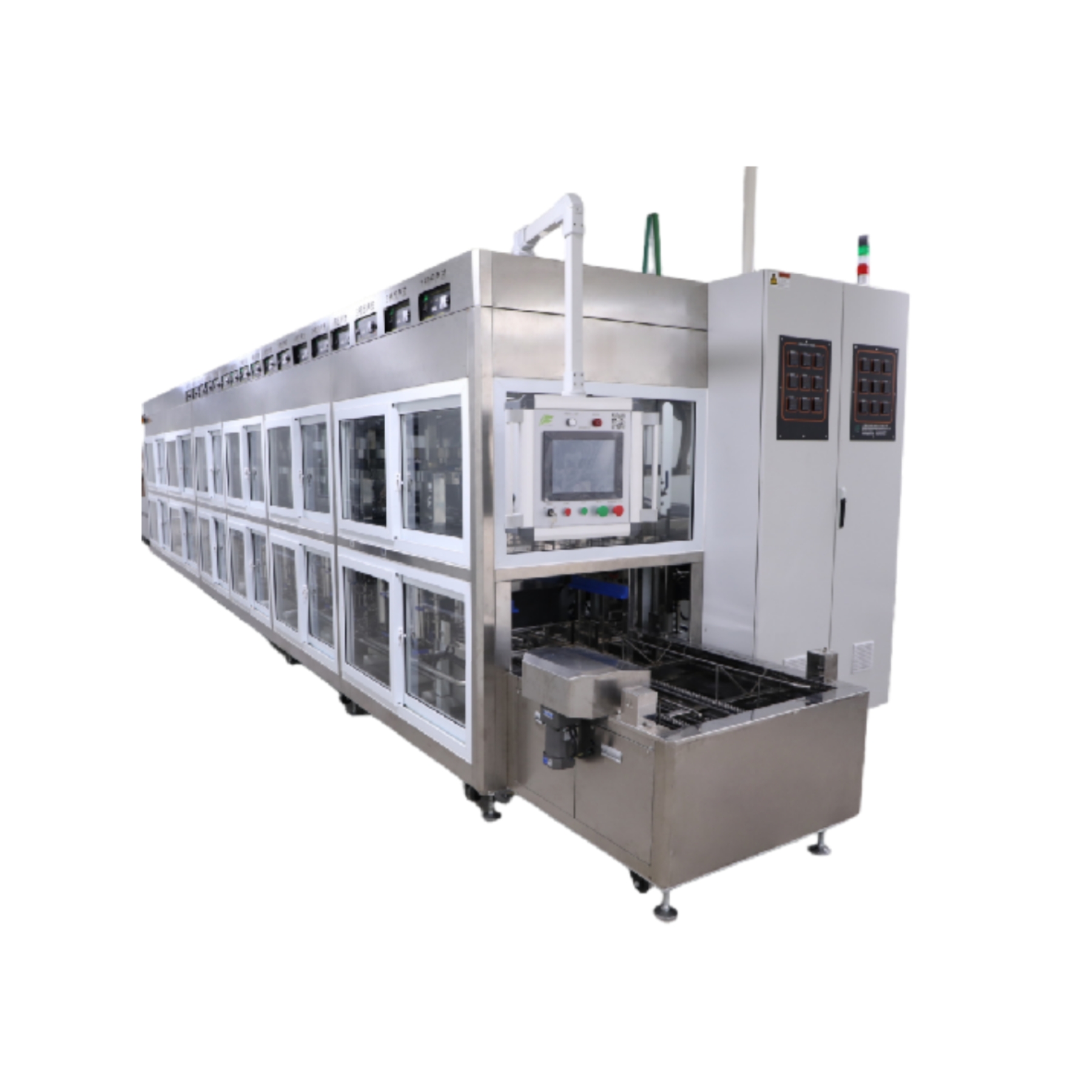

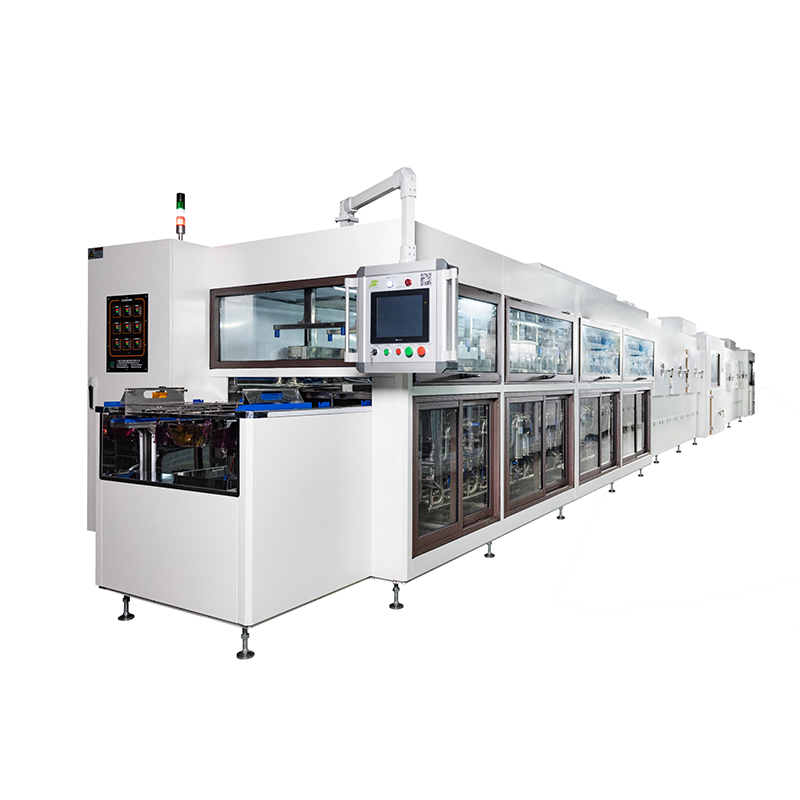

- Fully automatic multi-arm cleaning machine

- Fully automatic high-pressure cleaning machine

- Automatic hardware cleaning machine

- Fully automatic solvent cleaning machine

- Spray cleaning machine

- Ceramic ultrasonic cleaning machine

- Semiconductor ultrasonic cleaning machine

- Components Ultrasonic cleaning machine

- Semiconductor target material cleaning machine

- Semiconductor ring component pickling machine

- ABOUT US

- NEWS

tangxuan@sf-sh.com

-

Slovenian

Slovenian

-

Slovak

Slovak

-

Latvian

Latvian

-

Bosnian

Bosnian

-

Icelandic

Icelandic

-

Ukrainian

Ukrainian

-

Georgian

Georgian

-

Serbian

Serbian

-

Croatian

Croatian

-

Belarusian

Belarusian

-

Romanian

Romanian

-

Estonian

Estonian

-

Hungarian

Hungarian

-

Czech

Czech

-

Catalan

Catalan

-

Norwegian

Norwegian

-

Lithuanian

Lithuanian

-

Albanian

Albanian

-

Hindi

Hindi

-

Italian

Italian

-

Finnish

Finnish

-

Arabic

Arabic

-

Danish

Danish

-

Bulgarian

Bulgarian

-

Thai

Thai

-

Polish

Polish

-

Swedish

Swedish

-

Greek

Greek

-

Portuguese

Portuguese

-

Dutch

Dutch

-

Spanish

Spanish

-

Turkish

Turkish

-

Russian

Russian

-

Deutsch

Deutsch

-

French

French

-

Korean

Korean

-

Japanese

Japanese

-

English

English

Leave A Comment