Product Introduction

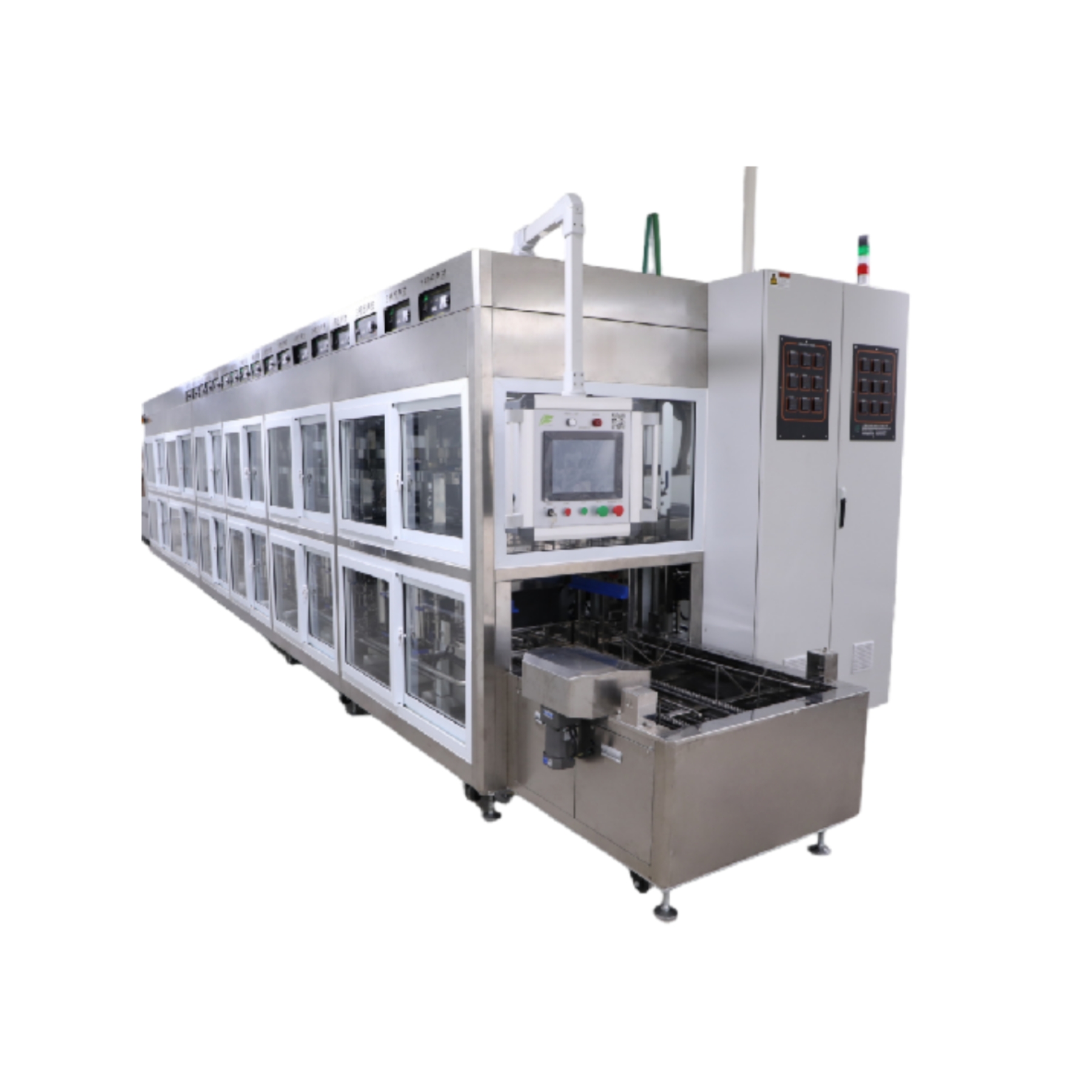

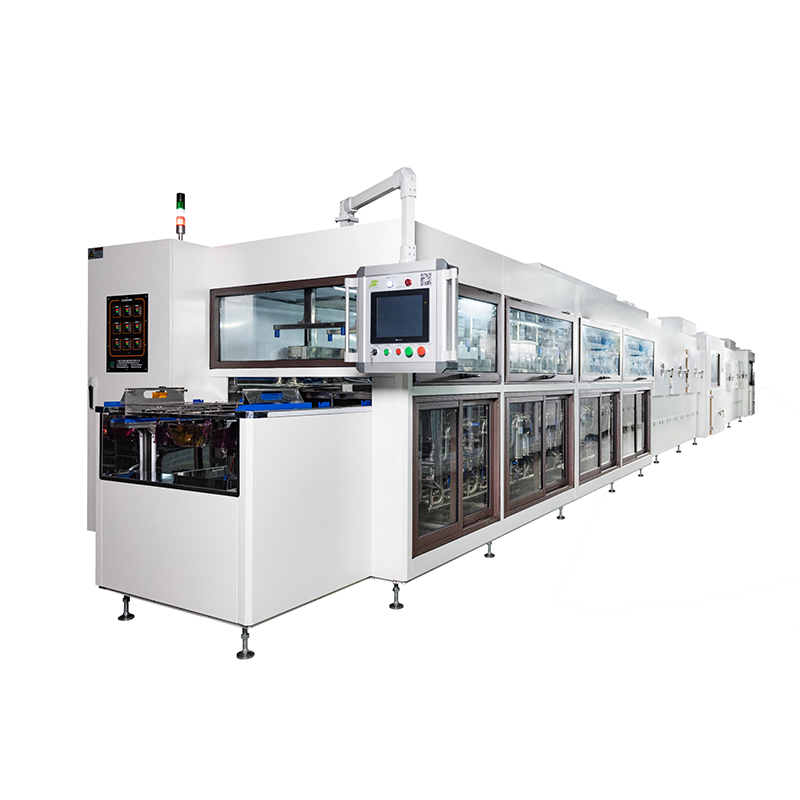

The spray cleaning machine is a highly efficient cleaning device specially developed for batch production of small and medium-sized hardware parts, automotive components, electronic casings, stamping parts, and injection molded parts. It integrates the full-process automated functions of "high-pressure spray + rotary cleaning + segmented rinsing + hot air drying". Using water-based/neutral cleaning agents as the medium, a dense jet is formed through high-pressure spraying to impact the surface and crevices of the workpiece, quickly stripping away contaminants such as oil stains, dust, and residual cutting fluid. It meets the efficient cleaning requirements in batch production in the manufacturing industry, especially suitable for workpieces with relatively simple structures that need to be processed in batches.

Core advantages (Exclusive features for spray cleaning)

- High-pressure dense spray: Equipped with multiple adjustable spray arms, the spray pressure is 3-15 mpa, the nozzle density is ≥12 per square meter, forming a 360° jet coverage without blind spots. The single piece cleaning time is as low as 1-3 minutes, and the production capacity can reach 1000-5000 pieces per hour.

- Multi-station continuous operation: It adopts tunnel or rotary structure, supporting continuous operation of feeding, cleaning, rinsing, drying and discharging without manual transfer, with a high degree of automation.

- Wide material compatibility: It can be adapted to various material workpieces such as metal (steel, aluminum, copper, zinc alloy), plastic (ABS, PC, PP), ceramic, etc. By adjusting the pressure and the type of cleaning agent, it can prevent workpiece corrosion or damage.

- Energy conservation, environmental protection and economy: Equipped with a cleaning agent circulation filtration system (filtration accuracy 5-10μm), the cleaning agent recovery rate is ≥90%, and the water-saving rate is 40% higher than that of ordinary cleaning equipment. The hot air drying adopts a waste heat recovery design, reducing energy consumption by 25%.

- Flexible and convenient operation: PLC programmable control, supports storage of over 60 cleaning schemes, and can adjust the spray pressure, temperature and time according to the size of the workpiece and the degree of contamination. The touch screen operation is intuitive and easy to understand.

Working principle

The equipment achieves efficient cleaning of workpieces through a continuous process of "continuous conveying → multi-stage spray cleaning → graded rinsing → hot air drying". The core logic is as follows:

3.1 Continuous conveying and positioning

Tunnel type: The workpieces are conveyed at a uniform speed through the conveyor belt. When passing through each workstation, the spray arms rotate 360° around the workpieces to spray water, ensuring full coverage.

Rotary type: The workpiece is placed in the rotating basket, which drives the workpiece to rotate slowly. Combined with the fixed spray arm, it achieves thorough cleaning without dead corners.

3.2 Multi-stage spray cleaning

Pre-washing station: Low-pressure spray (3-5 mpa) is used to initially wash away the floating dust and large amounts of oil stains on the surface of the workpiece, reducing the contamination of the cleaning agent at the main washing station.

Main cleaning station: High-pressure spray (8-15MPa) + 40-70℃ warm cleaning agent, jet impact on the surface and crevices of the workpiece, quickly peeling off stubborn oil stains and impurities, fan-shaped nozzles expand coverage area, direct nozzles penetrate deep holes for cleaning.

Rinsing station: The first stage of circulation rinsing removes the residual cleaning agent on the surface of the workpiece, and the second stage of pure water spray thoroughly removes impurities to prevent the surface of the workpiece from becoming mottled due to residue.

3.3 Hot Air Drying

The hot air circulation system blows the heated clean air towards the workpiece. Combined with the waste heat recovery device, it accelerates the evaporation of moisture. The workpiece is dried at a low temperature of 60-120℃ to prevent deformation, ensuring that the surface of the workpiece is dry without water marks or residues, and can directly enter the assembly or packaging process.

3.4 Medium circulation regeneration

The wastewater after cleaning and rinsing undergoes multi-stage treatment through filter screens, oil-water separators, and precision filters to remove impurities and floating oil. The cleaning agent is then recycled to the corresponding workstations for reuse. Part of the pure water rinsing wastewater is recovered for pre-washing, significantly reducing the consumption of consumables and water resources.

This equipment can be designed, developed and manufactured according to different product specifications and production capacities.

Slovenian

Slovenian

Slovak

Slovak

Latvian

Latvian

Bosnian

Bosnian

Icelandic

Icelandic

Ukrainian

Ukrainian

Georgian

Georgian

Serbian

Serbian

Croatian

Croatian

Belarusian

Belarusian

Romanian

Romanian

Estonian

Estonian

Hungarian

Hungarian

Czech

Czech

Catalan

Catalan

Norwegian

Norwegian

Lithuanian

Lithuanian

Albanian

Albanian

Hindi

Hindi

Italian

Italian

Finnish

Finnish

Arabic

Arabic

Danish

Danish

Bulgarian

Bulgarian

Thai

Thai

Polish

Polish

Swedish

Swedish

Greek

Greek

Portuguese

Portuguese

Dutch

Dutch

Spanish

Spanish

Turkish

Turkish

Russian

Russian

Deutsch

Deutsch

French

French

Korean

Korean

Japanese

Japanese

English

English

Leave A Comment